Best Pratice Environmental Management Guidelines for Recirculating Aquaculture Systems

Fisheries Management Report No. 37 April 2008

ISSN: 1448-1693

ISBN: 1-74146-847-7 (print)

ISBN: 978-1-74199-796-5 (internet)

Department of Primary Industries (2008). Best Practice Environmental Guidleines for Recirculating Aquaculture Systems. Fisheries Victoria Report Series No. 37.

Disclaimer: This publication may be of assistance to you but the State of Victoria and its employees do not guarantee that the publication is without flaw of any kind or is wholly appropriate for your particular purposes and therefore disclaims all liability for any error, loss or other consequence which may arise from you relying on any information in this publication.

Executive summary

Recirculating aquaculture systems (RAS) are broadly defined as "…self-contained farming systems that require minimal water exchange due to the internal recycling of water and use of biological and mechanical filters" (ORR 1999). The development of commercial-scale RAS has been stimulated primarily by interest in producing high-value warm water fish and eels. Recirculating aquaculture systems overcome the constraints imposed by temperate climates and other environmental factors by providing a controlled, predictable and biosecure environment for the culture species.

About ninety per cent of RASs in Victoria are privately owned, commercial systems with the remainder operated for the purposes of research and or training. The primary species produced in RASs are Murray cod, barramundi and eels. A wide variety of RAS designs operate in Victoria but the basic components and principles of operation are common to most systems.

Although they require reliable supplies of high quality water to function efficiently, RASs utilise relatively small amounts of water per unit of production compared to other aquaculture technologies. Other inputs to RASs include fish, aquaculture feeds and chemicals which may include therapeutants.

Wastes generated in RASs can be divided into the following categories: organic matter, mainly uneaten feed and fish excreta, in effluents; solid wastes captured in filters and/or settlement ponds; chemicals and therapeutants; fish mortalities and processing wastes; fish escapes; and energy and greenhouse gas emissions.

Environmental impacts associated with RASs are identified and prioritised in this report with respect to their importance at an industry level. While the high level of control and enclosed nature of RASs generally lowers their environmental impacts when compared to other aquaculture technologies, many of these impacts can be mitigated during site selection and the facility design phases. The issues identified are therefore linked with appropriate best practice management actions for new farms (i.e. site selection, farm design and construction) and existing farms (i.e. operational management).

Best Practice Environmental Management Guidelines for Recirculating Aquaculture Systems provides a mechanism through which the industry can demonstrate its environmental credentials and continue to grow and improve.

An essential requirement of RAS best practice environmental management (BPEM) is compliance with relevant regulatory requirements particularly during the site selection, farm design and construction phases and operation.

Sound site selection and farm design allows developers to mitigate potential impacts prior to construction and make the application of BPEM principles adoption of the principles of cleaner production more effective. Key areas to be considered during site selection are: location of the facility; site topography and geology; access to quality water; environmental sensitivity of the site; climatic factors; and options for effluent disposal.

To achieve BPEM in farm design, the following factors that should be considered: design aesthetics; impacts on flora and fauna; prevention of fish escapes; water source; quantity and quality of water required; water recirculation; biological and mechanical filtration; aeration, oxygenation and degassing; disinfection; biosecurity; energy efficiency; effluent disposal; sludge management; and mortalities and processing waste disposal.

The primary areas of RAS operational management relate to: water; stock; feed and feeding; and animal health.

Effective operational management of RASs results in stable environmental conditions that optimise fish growth and survival. Unstable and or sub-optimal conditions increase the amount of wastes produced that can adversely impacts the environment. Appropriate waste minimisation strategies reduce these impacts and ensure the long-term environmental health of the farm site

Real-time monitoring that provides accurate information about RAS performance and alarm systems are essential. Critical systems, including power, should be reliably backed up to minimise the impacts of mechanical breakdowns, inefficient operation and accidents.

Introduction

Increasing interest in producing high-value warm water fish including Murray cod, barramundi and eels has led to the development of enclosed, recirculating aquaculture systems (RAS). Many parts of Victoria are not warm enough to achieve year-round commercial growth rates of these aquatic species. Recirculating aquaculture systems provide a controlled and biosecure environment that can allow for species to be commercially produced outside of their natural range.

In the context of this report, RAS are defined as "…self-contained farming systems that require minimal water exchange due to the internal recycling of water and use of biological and mechanical filters" (ORR 1999).

Optimising production efficiency by minimising, re-using and treating wastes underpin the design of RASs and are crucial to the economic viability of these systems. These characteristics embody the cleaner production and waste minimisation policies of the Victorian Government.

Many of the environmental issues associated with traditional aquaculture systems relate to the utilisation and discharge of water. The enclosed, intensive nature of RAS significantly increases the efficiency of water consumption and discharge and thus mitigates many of the environmental impacts of other aquaculture practices (Losordo et al. 1992). In addition, RASs require less land than conventional aquaculture technologies.

Specifically, BPEMGs can offer the following advantages to the RAS aquaculture industry (Seafood Services Australia 2002):

- improve economic efficiency through waste reduction;

- demonstrate industry's recognition of relevant environmental issues and its responsible and sustainable use of natural resources;

- develop and maintain relationships with local communities through industry commitment to responsible environmental performance;

- secure and maintain access to domestic and export markets; and

- demonstrate compliance with relevant legislation and regulations.Best practice environmental management positively integrates the RAS industry's environmental credentials with its long-term competitiveness.

Objectives of the BPEMG

Best practice environmental guidelines provides a mechanism for industry to demonstrate its environmental credentials and continue to grow and improve.

The broad objective of this BPEMG is to assist RAS developers and operators to design and build sustainable and efficient programs and systems to maximise environmental performance and achieve best practice standards. Best practice environmental management of the ornamental fish aquaculture sector is not within the scope of this document.

A framework for RAS operators to create site-specific environmental improvement plans or environmental management systems is developed in this BPEMG . Developing this framework required assessing existing practices, identifying the main environmental issues and suggesting methods to minimise impacts.

Specifically, these guidelines provide information on:

- RAS farming practices;

- system components, principal inputs and wastes generated;

- benchmarking current management practices;

- the regulatory environment under which RASs operate;

- identification and evaluation of potential environmental impacts of RAS and the associated risks to industry;

- BPEM detailing strategies to minimise environmental impacts during site selection, farm design and construction; and

- BPEM during operational management.

These guidelines are outcome oriented and not intended to be prescriptive, definitive or inflexible. Farmers are encouraged to consider alternative, innovative means to meet their environmental objectives and to apply the best site-specific solutions available to them.

RAS industry in Victoria

The Victorian RAS aquaculture industry

In 2005/06 there were 22 commercial, three educational and one government research RAS facilities in Victoria (Table 1).

Table1. RAS in Victoria 2005/06 (Department of Primary Industries, unpublished data).

|

Number of RAS | |

|

Commercial systems |

22 |

|

Government, training, and research and development |

4 |

|

Total Number of RAS |

26 |

Murray cod (Maccullochella peelii peelii) and barramundi (Lates calcarifer), are the principle species produced in Victorian RAS. Barramundi is a popular choice for aquaculture in RAS due to its relatively short production cycle, recognised market and tolerance to a range of water quality conditions.

With the development of Asian markets, shortfin and longfin eels (Anguilla australis and A. reinhardtii, respectively) production has increased in recent years. The life-cycle of these species is not closed and glass or larger eels for stocking in RAS must be obtained from the wild or from licensed producers. Lesser amounts of rainbow trout (Oncorhynchus mykiss), silver perch (Bidyanus bidyanus), golden perch (Macquaria ambigua) and yabbies (Cherax destructor) are produced in RAS facilities. Small-scale production of Australian bass (M. novemaculeata), black bream (Acanthopagrus butcheri), sleepy cod (Oxyeleotris lineolata) and snapper (Pagrus auratus) has been undertaken for commercial, research and restocking purposes.

Approximately 71 per cent of RAS facilities, which includes all government and training facilities and most research and development facilities, produce less than ten tonnes per annum. Nineteen per cent of RASs produce ten to 50 tonnes per annum and the remainder produce more than 50 tonnes per annum.

System components

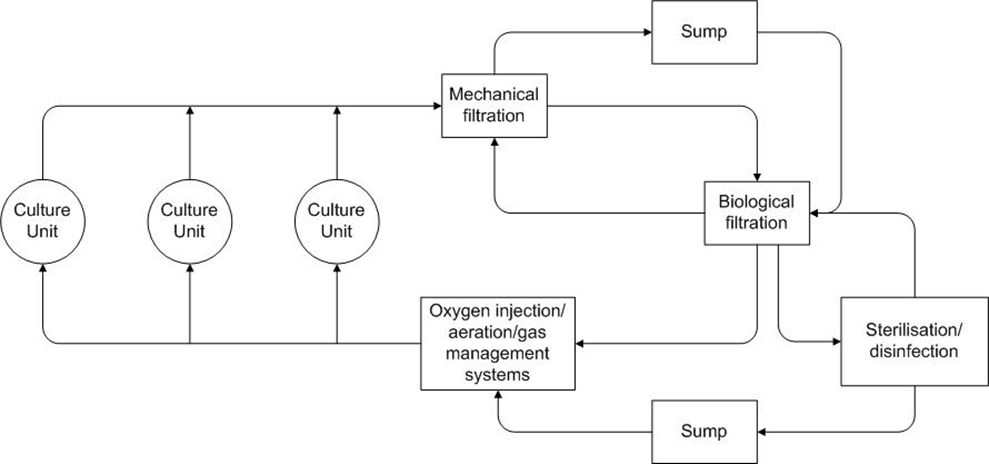

A schematic diagram of a typical RAS design is shown in Figure 1. Principal system components include:

- tanks or culture units;

- oxygen injection, aeration and carbon dioxide management systems;

- biological filtration;

- mechanical filtration;

- disinfection and or sterilisation; and

- temperature control systems.

Tanks or culture units

Tanks are constructed of a variety of materials including concrete, plastic and fibreglass. Tank depth range from a few centimetres for hatchery troughs to several metres. The volume of tanks used for nurseries and growout range from 0.1 to 2 m3 and 1 to 20 m3, respectively.

Circular tanks with flat or sloping bases drain to a central outlet are common but rectangular tanks are used in some cases.

Oxygen injection, aeration and carbon dioxide management systems

The oxygen demands of fish and bacteria in RAS, unless effectively managed, can result in the dissolved oxygen (DO) concentration of the aquatic environment falling below optimal levels and thus limiting production. Dissolved oxygen concentrations in aquaculture systems are managed through oxygen injection using liquid or oxygen separation systems, or aeration.

As stocking densities increase, the ability of a system to maintain DO concentrations at an acceptable level using passive diffusion will diminish. While low-intensity RAS (5 to 40 kg/m3) commonly use air blowers or other devices (e.g. venturi systems) to assist in managing DO levels, the increased oxygen demand of more intensive systems requires that oxygen be injected into the water stream.

Figure1. Schematic diagram of a generic recirculating aquaculture system.

Carbon dioxide results from respiration by aerobic organisms including fish and bacteria. If the carbon dioxide concentration in a system become excessive it can have a narcotic effect on stock, reducing their rate of feeding and growth.

Effective carbon dioxide control is accomplished using vigorous aeration, chemicals to adjust pH or a combination of these methods.

Biological filtration systems

Biological filters, or biofilters, use bacteria to remove the toxic metabolic by-product ammonia resulting from the metabolism of protein by stock and other organisms. Bacteria convert ammonia to another toxic compound, nitrite, which is then converted to the less toxic compound, nitrate. Biofilters in RAS expand the surface available for bacteria to grow and thus increase the overall rate at which nitrification occurs.

A variety of materials including PVC-pipe shavings, micro-beads, oyster mesh, rock and engineered biofiltration media, are used in biofilters. Common characteristics of effective biofilter media are a high surface area to volume ratio and low likelihood of clogging or creation of channels through the media.

The most commonly used biofilters in Victorian RAS are trickling type. In trickling biofilters, water is pumped to the top of the biofilter and allowed to drip downward through the biofilter media.

Biofilters should be designed to process the maximum expected daily load of total ammonia nitrogen (TAN). The appropriate surface area and volume of media required can be calculated from the TAN load and the nitrification rate of the filter (Hutchison et al. 2004).

Solid waste removal systems

Solid wastes result primarily from fish faeces and uneaten fish food. It is important this material is quickly and efficiently removed from the aquatic environment as it rapidly decomposes and can negatively affect water quality.

Solids may be removed at several points in a RAS including:

- tank outlets with dual outlets installed;

- sumps and settlement tanks;

- hydro-cyclones or swirl separators; and

- mechanical filters including drum filters.

Disinfection systems

Where the water supply may contain pathogens, disinfection prior to use is essential to minimise the risk of disease outbreaks. Disinfection is also used within culture systems and in treating effluent prior to discharge. Methods of disinfection include chlorine, ozone, ultraviolet radiation and heat (Appendix A).

Temperature control systems

Operators of RASs often heat or cool water to optimise growth rates and enable non-endemic species to be grown outside of their natural range. The most effective and efficient method is counter-current heat exchange systems. When using trickling or rotating filters, water can be warmed or cooled passively via heating the air although direct heating is significantly more efficient. Immersion heaters, although convenient, are inefficient and impractical with large volumes of water. Effectively insulating buildings assists in maintaining desired temperature levels and reduces energy requirements (Remmerswaal 1993).

Increasing or decreasing water temperatures can be used to maximise or hold-back fish growth. By altering water temperature regimes, aquaculture producers can manage the reproductive cycle of broodfish (Summerfelt et al. 2001) and initiate out-of-season spawning of some species.

Principal inputs to RASs

Fish

Murray cod (Maccullochella peelii peelii), barramundi (Lates calcarifer), shortfin eels (Anguilla australis) and longfin eels (A. reinhardtii) are the primary species cultured in RASs in Victoria. Juvenile glass eels or larger eels obtained from the wild are on-grown for restocking or for sale to overseas markets. Lesser amounts of market-size silver perch (Bidyanus bidyanus) and Australian bass (Macquaria novemaculeata) and black bream (Acanthopagrus butcheri) fingerlings have been produced.

Some operators use RASs to culture yabbies (Cherax destructor) for sale and stocking, for producing juveniles out of season and purging prior to sale.

Water

Water quality is critical to the well-being of stock, the economic performance of the business and the efficiency of the RAS. Maintaining water quality parametres within the optimal range of the cultured species is critical to success (Appendix B; ANZECC 2000). Compared to other aquaculture technologies, the higher levels of water reuse in RAS lowers water consumption per tonne of fish production (Table 2).

System volumes of RASs in Victoria range from 1.0 m3 up to approximately 400 m3. The average volume is 103 m3. Following initial filling, the average daily water exchange rate[1]for RASs in Victoria ranges from less than one per cent to about fifteen per cent; the average exchange rate is 7.8 per cent. The daily exchange rate depends primarily on husbandry methods (e.g. feeding rates, stocking density, animal health management), efficiency of water treatment and water availability.

Table2: Quantities of water required for production in aquaculture systems.

|

System |

Water requirement (m3/tonne fish) |

Reference |

|

Scottish salmon hatchery |

50–1,190 |

Kelly and Stellwagen (1997) |

|

Danish pond-based trout farm |

560–4,150 |

Kelly and Stellwagen (1997) |

|

Victorian flow-through (diversion) salmonid farm |

200–800 |

B. Ingram, personal communication. |

|

Victorian RAS |

0.15–0.5 |

B. Ingram, personal communication. |

There is a clear link between the level of water re-use and water consumption, the requirement for oxygenation to maintain acceptable DO levels and the concentration of waste in the effluent stream. At a constant level of feeding, fish biomass and harvesting, a reduction in the proportion of water reuse will reduce the amount of water available to remove wastes. The result is the concentration, but not the mass, of wastes in the effluent stream will increase and there will be a greater need for oxygenation and biological and mechanical filtration.

Feeds and feeding

Feed, which is the cause of the nutrient wastes discharged from RAS, can represent over forty per cent of the total aquaculture production costs. Efficient feeding practices, including using species-appropriate diets, will maximise growth and production rates and minimise environmental impacts and feed costs.

Inefficient feeding practices can lead to deteriorating water quality including an increase in solids, including faecal, and nutrient waste loads. Decomposing wastes promote bacterial growth, leach nutrients and can lead to lower dissolved oxygen concentrations and increased concentrations of ammonia and nitrite. It is important that feed wastage is minimised and that solid wastes are quickly removed from the aquaculture environment.

Feeding and feed performance is often measured as the ratio of the dry weight of food used to produce an amount of fish. This food conversion ratio (FCR) is used to benchmark and compare feed types, management practices and farm performance. Typical FCR values are between about 1.0 to 2.0 (i.e. it takes 1 to 1.5 kilograms of feed to produce 1 kilogram of fish).

Chemicals and therapeutants

Chemicals may be used in fish farming for a number of purposes (Table 3).

Disinfectants

Disinfectants used to clean equipment, sanitise footwear and for other purposes can minimise the risk of disease and pathogen transfer and are an important part of best practice management. Commonly used disinfectants include chlorine, iodine and sodium hydroxide-based products and hydrogen peroxide.

Therapeutants

Therapeutants used in aquaculture are applied externally or incorporated into diets of sick animals. Agricultural and veterinary chemicals must be registered and used in accordance with Commonwealth and Victorian legislation.

The most commonly used therapeutants are formalin and salt. Antibiotic use in Victorian aquaculture is rare and generally limited to major disease outbreaks.

Feed additives

Feed additives include vitamins to ensure optimal growth and increase resistance to disease and pigments to enhance product acceptance. Additives are usually added during feed manufacture although in some cases may be applies as a top-dressing.

Anaesthetics

Anaesthetics are used to sedate fish and reduce stress during handling and harvesting. Anaesthetics should be used in accordance with relevant Commonwealth and Victorian legislation.

Hormones

Hormones including methyl-testosterone are used to manipulate the sex of stock and to induce spawning in broodstock. Hormones should be used in accordance with relevant Commonwealth and Victorian legislation.

Fuels

Diesel and petrol are the primary fuels used on salmonid farms for machinery and generators.

Table 3: Chemicals[2]used in the aquaculture industry in Victoria.

|

Use |

Chemical |

Comments |

| Disinfectants | Chlorine-based | Essential for the control of disease and pathogen transfer. |

| Iodine-based | ||

| Sodium hydroxide | ||

| Hydrogen peroxide | ||

| Theraputic chemicals | Formalin | Use is authorised under a Minor Use Permit for the APVMA |

| Antibiotics | Use of antibiotics extremely rare. Must be prescribed by a veterinary surgeon. | |

|

Feed additives |

Pigments | Based on natural pigments. Only used in some species. |

| Vitamins and minerals | Required for a balanced diet. | |

| Bioactive compounds | Can enhance immune system, but not usually used. | |

|

Anaesthetics |

Aqui-S, Benzocaine. | Minor use permit required. |

|

Hormones |

Oviprim, Chorulon | Injected directly into brood fish. Used under permit from APVMA or under veterinary prescription. |

|

Fuels |

Diesel, petrol, LPG | Used for machinery and on-farm equipment. |

Principal RAS wastes and their components

Many of the environmental impacts of aquaculture are associated with the wastes generated. Wastes produced in RASs can be broadly divided into the following categories:

- organic matter (mainly uneaten feed and fish excreta) in effluent;

- solid wastes from filters or settlement ponds;

- chemicals and therapeutants;

- fish mortalities and processing wastes;

- fish escapes; and

- energy and greenhouse gas emissions.

Effluent and filter sludge flows can be combined and discharged together or disposed of separately. To clearly demonstrate the differences between these waste streams, they are discussed separately.

Effluent characteristics

Different feeding and management strategies used by RAS managers can result in substantial differences in:

- the character of the effluent;

- the efficiency of feed consumption and assimilation;

- water exchange rates;

- water recycling and treatment prior to discharge; and

- physiological factors (e.g. temperature, body size, health and stress).

Table 4 summarises effluent quality data where solid and liquid wastes are discharged together (Boreham et al. 2004). The study illustrates differences in the characters of the waste streams.

Effluents from RASs are not generally discharged to surface waters. Under trade waste agreements, the majority of RAS in Victoria discharge effluent to sewer systems and pay for it to be treated by a water authority on a volume and composition basis.

Effluent from RAS in rural areas is often used to irrigate and fertilise horticulture or pasture crops.

Table 4: Water quality parameters (mean in brackets) from an intensive RAS (Adapted from Boreham et al. 2004).

|

Parameter |

Within system |

Post up-flow filter (Liquid effluent) |

Drum filter effluent (Solid wastes) |

|

Temperature (oC) |

17–22.8 (19.8) |

18.1–22 (19.4) |

18–21.7 (19.4) |

|

Dissolved oxygen (mg/L) |

6.2–17.4 (10.2) |

6.7–9.2 (8.0) |

4.2–7.5 (5.7) |

|

Carbon dioxide (mg/L) |

16.9–40.8 (28.2) |

21.0–39.8 (30.4) |

28.2–46.2 (37.2) |

|

pH |

5.4–6.8 (6.1) |

5.4–6.6 (6.0) |

5.4–6.8 (6.4) |

|

Total ammonia nitrogen (mg/L) |

20.2–37 (30.1) |

20.4–36.3 (29.0) |

22.8–51 (36.3) |

|

Unionised ammonia nitrogen (mg/L) |

0.003–0.089 (0.02) |

0.003–0.056 (0.013) |

0.005–0.123 (0.044) |

|

Nitrite (NO2-N) (mg/L) |

0.03–1.22 (0.32) |

0.10–0.81 (0.26) |

0.21–1.78 (0.68) |

|

Nitrate (NO3-N) (mg/L) |

7–95 (46) |

13–95 (46) |

19–88 (50) |

|

Total phosphorous (mg/L) |

2.7–42.5 (12.8) |

4.5–42.5 (13.3) |

7.1–42.5 (21.5) |

|

Suspended solids (mg/L) |

0.2–54 (5.7) |

0.4–8.0 (2.8) |

26–719 (142) |

|

Biochemical oxygen demand (BOD-5 day) (mg/L) |

0–49 ( 11.7) |

0–24 (8.8) |

19–82 (46.5) |

|

Alkalinity (mg/l) |

0–28.5 (9.1) |

0.1–20.5 (7.7) |

10.8–120 (43.8) |

|

Turbidity (NTU) |

0–15 (5.8) |

0–11 (3.9) |

7–1343 (173.5) |

|

Dissolved solids (mg/L) |

44–1230 (351) |

44–1024 (320) |

52–1344 (402) |

The primary components of the effluent from RAS are:

- suspended solids;

- oxygen consuming wastes;

- nutrients; and

- toxic metabolites.

Suspended solids and oxygen consuming wastes

Suspended solids are mainly uneaten feed and faeces. Mechanical filtration (e.g. drum filter) can remove 30 to 80 per cent of the suspended solids from the effluent stream (Summerfelt and

Vinci 2002).

Biodegradable organic matter that is not completely removed by mechanical filtration can exert a significant oxygen demand in the aquatic environment. Kelly and Stellwagen (1997) demonstrated that 21 per cent of the biochemical oxygen demand (BOD) load remained after a particle-rich stream was passed through a 60 micron screen filter.

A reduction in suspended solid concentration and BOD can significantly improve the effectiveness of subsequent wastewater treatment systems e.g. ozone or ultraviolet light.

Nutrients

The majority of nitrogen and phosphorus is introduced to RASs in feeds that, depending on the efficiency of feeding, are eaten or wasted. A proportion of the food that is released back to the water as faeces and excreta is recycled within the culture system, resulting in the removal of phosphorous along with suspended solids and the conversion of nitrogen to other forms. This relocation of nutrients and organic matter, rather than an overall reduction, allows for environmental impacts to be reduced by facilitating effluent treatment (Piedrahita 2003).

Toxic metabolites

Toxic metabolites produced in RAS include ammonia and nitrite. Ammonia is a by-product of the metabolism of protein contained in feed and is excreted by fish. Depending on pH and temperature, it can be highly toxic.

Nitrite, an intermediate in the nitrification of ammonia to nitrate, is also toxic to fish. Effective biological filtration maintains the concentration of these compounds within limits acceptable to the cultured species. Inadequate biological filtration and other factors including poor feed management can result in elevated levels of ammonia and nitrite in RAS effluent.

Solid waste characteristics

The concentration and removal of suspended solids from RASs produces a sludge that, if not properly disposed of, can contaminate surface waters and groundwater. Filter sludge tends to contain the same components as liquid effluent but at higher concentrations. Studies have reported that at food conversion ratios of 1.2:1, one litre of sludge is produced for each kilogram of feed fed on a salmon farm (Bergheim et al. 1993).

Conventional sedimentation and micro-screen filtration processes typically remove 30 to 80 per cent of the solids from a waste stream (Summerfelt and Vinci 2002). A fraction of the solids contained in the treated effluent can be captured within settling basins and removed as a thickened sludge containing three to ten per cent solids (Westers 1991; Bergheim et al. 1993; Chen et al. 1997; Summerfelt 1999).

Sludge treatment options used by RAS managers include:

- combining sludge with liquid effluent and transferring to domestic wastewater treatment facilities; and

- concentration of solid wastes by filtering or settling in ponds.

- In the latter case, the solid wastes may then be disposed of by:

- on-site burial;

- disposal at a land-fill;

- composting; and

- use as a crop fertiliser.

Chemicals

Categories of chemicals used in aquaculture are listed in Table 3. The quantity and type of chemicals that enter waste streams depends on the mode of application. Chemicals most likely to be discharged as wastes are those administered directly to water (e.g. salt, formalin) and those contained in feeds (e.g. pigments, vitamins and minerals and hormones). Chemicals may also enter the waste stream through accidents or spills.

Chemicals must be used carefully in RAS as those containing salt or chlorine may have a negative impact on biofiltration. Some chemicals leave residues in the fish flesh or effluent. The implications of using chemicals should be carefully considered prior to administration and use should be in accordance with label instructions and relevant legislation.

Fish mortalities and processing wastes

Fish mortalities are a normal occurrence in aquaculture production and must be promptly removed from culture units and disposed of. Processing wastes (primarily blood, viscera, heads and frames) are generated when fish are gilled and gutted on-site prior to transfer to market.

While fish mortalities have routinely been buried on-site at most large farms, some farms compost wastes and dispose of the composted material by land application. Liquid wastes that result from fish processing are generally discharged to septic or sewer systems.

It should be noted that fish mortalities and processing wastes are prescribed wastes and can only be disposed to landfills that are licensed to accept this waste. Transport of these wastes is a scheduled activity and can only be undertaken with appropriate transport permits issued by the EPA.

Fish escapes

The design of most RASs makes them inherently biosecure and stock escape is unlikely. When employed, screening devices designed to prevent stock escape must be of the appropriate size and in working order.

Energy and greenhouse gas emissions

Recirculating aquaculture systems are heavily reliant on energy with significant amounts consumed during pumping, lighting, heating and cooling, feeding and waste disposal. Inefficient mechanical equipment (e.g. pumps and heating/chilling equipment), management (e.g. overfeeding) and biological processes (e.g. biofilter operation) can result in higher than expected energy consumption and greenhouse emissions.

Early RAS developments were generally not economically viable due to high energy requirements and other costs. In more recent times, the use of greenhouses and insulated buildings has reduced energy loss caused by heat and evaporation and maintenance of low food conversion ratio values has reduced feed wastage. There may be opportunities to link RASs with other agricultural systems such as hydroponics that use wastewater and carbon dioxide produced by the biofilter.

Statutory requirements for RAS

This section is a summary of the statutory requirements, non-legislative policies and strategies relating to RAS in Victoria. Legislation relating to RAS falls into five general categories:

- planning legislation;

- water diversion legislation;

- aquaculture legislation; and

- environmental legislation.

The onus is on the developer to be aware of and to comply with all relevant legislation which may change from time to time. Current Victorian legislation and regulations are available at www.legislation.vic.gov.au.

Planning legislation

Before construction of a RAS on freehold land can begin, planning permission from the relevant local authority may be required. The local authority also functions as the coordinating body for referral agencies.

The Planning and Environment Act 1987 (Victoria) empowers planning authorities to make planning schemes over any land in Victoria including land covered by water (ORR 1999). The Victorian Planning Provisions (VPP)(DSE 2008) is the reference document from which planning schemes are sourced and constructed. Aquaculture is a discretionary use in all VPP zones (DPI 2005).

Under the existing VPP, a permit is required for most of the standard zones with the exception of the Farming Zone and the Rural Activity Zone.

Industrial zones are appropriate for RAS. Table 5 shows the rural zones for which a permit for aquaculture is required (as specified in the Rural Zones Review)(DPI 2005).

Permits may also be required for:

- removal of native vegetation;

- access to certain roads; and

- car parking dispensation.

Water use legislation

Licences for water diversion and works on waterways may be required prior to developing aquaculture facilities.

Water diversion licence

Under the Victorian Water Act 1989, a water diversion licence is required from the appropriate Rural Water Authority (RWA) for extracting and using water from a waterway or bore and for alterations to the riverine environment for the purpose of extracting water. A water diversion licence authorises the holder to divert and use a specified amount of water from a specified waterway for aquaculture purposes. It specifies the maximum rate of diversion in megalitres (ML) per day, maximum daily volume, total annual volume and the land on which the water is to be used. This is an annual renewable, fee-based licence.

Under the recent Farm Dams Amendment to the Water Act 1989, a licence is required from the relevant water authority for dams or reservoirs constructed for commercial or industrial water supply purposes. This may include RAS developments.

Licence to undertake works on waterways

Under the Water Act 1989, a licence from the relevant RWA is required to undertake work within the bed or on the banks of a river or stream waterway.

Aquaculture legislation and policy

Under the Victorian Fisheries Act 1995, an aquaculture licence is required to engage in aquaculture on private or Crown land for commercial purposes[1]. Entitlements and conditions of aquaculture licences are established in the Fisheries Regulations 1998 and licences are renewable annually.

The Fisheries Act also provides for the protection of recreational and commercial fisheries, protected aquatic biota including those listed under the Victorian Flora and Fauna Guarantee Act 1988 and from the spread of declared noxious aquatic species.

Operators who move fish or seedstock intra-or interstate must comply with the Guidelines for the Translocation of Live Aquatic Organisms in Victoria (DPI 2003) and the Victorian Protocol for the Translocation of Aquatic Animals to Recirculating Aquaculture Systems (DPI 2008) and any other relevant translocation policies.

Table 5: Aquaculture use and development in rural zones (Adapted from DPI 2005).

|

Zone |

Permit for aquaculture |

Building and works |

|

Farming |

Not required |

Permit required for:

|

|

Rural Activity Zone |

Not required |

As above. |

|

Rural Living Zone |

Required |

Permit required. |

|

Rural Conservation Zone |

Required |

Permit generally required. |

Environmental legislation

The Victorian Environment Protection Act 1970 and subordinate legislation, State Environment Protection Policies (SEPP), are designed to protect beneficial uses downstream of any discharge or activity, licensed or otherwise. This Environment Protection Act is administered by the Environment Protection Authority Victoria (EPA) and provides for the control of water, air and land pollution, industrial waste and the emission of noise.

Under the Environment Protection Act, discharges of wastes to the environment must conform to the SEPP that identifies beneficial uses for particular segments of the environment and establishes ambient objectives and discharge limits.

Fish farms with design water flow rates in excess of 0.2 ML/day are designated as Scheduled Premises and require a discharge licence under the Environment Protection Act. Only fish farms that discharge or deposit waste solely to land are exempt from the licensing requirement.

Under the Environment Protection (Scheduled Premises and Exemptions) Regulations 2007, scheduled premises are subject to the works approval and licensing provisions of the Environment Protection Act. A works approval must be obtained before beginning construction of new works or making alterations to existing Scheduled Premises where waste discharge will be changed in any way.

Animal effluent and residues including fish processing wastes are classified as prescribed wastes under Schedule 1, Environment Protection (Prescribed Waste) Regulations 1998 and require the conditions detailed in the regulations to be adhered to when transporting and depositing waste off-site (EPA 1998).

The Commonwealth Environmental Protection and Biodiversity Act 1999 (the EPBC Act) protects the environment, particularly matters of National environmental significance. Developers of aquaculture facilities should understand the requirements of EPBC Act that relate to their undertakings.

Aboriginal heritage legislation

Aboriginal cultural heritage including human remains and burial sites, scarred trees where bark has been removed for a canoe, artefact scatters from stone tool manufacture, shell middens, rock art and natural features that are particularly significant to Aboriginal people is protected under the Aboriginal Heritage Act 2006 (Aboriginal Heritage Act). Aboriginal cultural heritage includes places with important Aboriginal association since European settlement.

Larger developments and many high impact activities in culturally sensitive landscapes can cause significant harm to Aboriginal cultural heritage. The Aboriginal Heritage Act prescribes in regulations, circumstances in which a Cultural Heritage Management Plan will be required for certain types of development or activities located in sensitive areas before they can commence.

Causing harm to Aboriginal cultural heritage is an offence under the Aboriginal Heritage Act. Stop Orders provide a process for stopping activities that threaten or harm Aboriginal cultural heritage. The Minister for Aboriginal Affairs can order a person to audit their activity under certain circumstances.

The Aboriginal Heritage Act includes a range of enforcement provisions including penalties of up to $1 million and clear powers for Heritage Inspectors.

Enquiries about the Aboriginal Heritage Act should be directed to Aboriginal Affairs Victoria, Department of Planning and Community Development (www.dpcd.vic.gov.au).

Environmental issues related to RAS

Due to the level of control and enclosed nature of RASs, environmental issues are generally less of a concern than those of other aquaculture systems such as pond and flow-through systems. This section identifies the environmental issues associated with RASs and evaluates and prioritises their importance at an industry level.

Potential environmental issues were identified at an industry Recirculating Aquaculture System Network (RAS-NET) meeting at the Marine and Freshwater Fisheries Research Institute (then Primary Industries Research Victoria), Snobs Creek in 2003. This workshop considered the importance of the issues at an industry level.

The environmental considerations which should be examined when developing and operating a fish farm include impacts on (after Gavine et al. 1996):

- the aquatic environment in terms of water and sediment quality;

- native flora and fauna;

- humans in terms of nuisance or risks to health; and

- the wider global environment.

For new farms, many of the environmental impacts identified can be minimised during the site selection and farm design processes. The tables in this section link specific issues with appropriate best practice management for new and existing farms.

Impacts on the aquatic environment

Impacts of fish farming on water and sediment quality occur primarily through inappropriate disposal of wastes. The nature of the impact and the risk that it will occur depends upon the specific waste source and waste concentration.

Three waste sources from RAS that could have detrimental effects on the aquatic environment are:

- discharge of liquid effluent;

- disposal of filter sludge; and

- disposal of mortalities and processing wastes.

The specific concerns related to these issues and their priority for the RAS industry are summarised in Table 6. Minimising these impacts through best practice environmental management is detailed in later chapters.

Discharge of liquid effluents

There are four main areas of concern with respect to the discharge of liquid effluents from RASs to surface waters. The risk of these events occurring is relatively low as few RASs in Victoria discharge to surface waters.

Suspended solids

Suspended solids, mainly fish faeces and uneaten feed, in the effluent stream can increase the turbidity of receiving waters, restrict light penetration and reduce the primary productivity of the site. Where water velocities are low, solids can settle and accumulate downstream of the discharge point, smothering or reducing the diversity of benthic communities.

Oxygen consumption

If the effluent has a high oxygen demand, localised deoxygenation of the water column can occur. This deterioration in water quality can have detrimental impacts on native fauna.

Nutrient enrichment

Nitrogen and phosphorous in RAS effluents may stimulate primary productivity and lead to algal blooms. Algal blooms can lead to reduced light penetration and localised variations in dissolved oxygen concentrations.

Toxic metabolites and chemicals

Some chemicals contained in effluent, including ammonia, nitrite, therapeutants and other chemicals, may be present at concentrations toxic to biota in the receiving waters.

Negative impacts can also occur through accidental spillage or inappropriate land application of effluent.

Table 6: Issues related to impacts on the aquatic environment.

|

Category |

Priority for RAS |

Specific Issue |

Refer to specified section in Best Practice Environmental Management |

|

Impacts of effluent discharge Note: Few farms discharge to surface waters |

Low |

Nutrient enrichment resulting from nitrogen and phosphorous in effluents Increased water turbidity and sedimentation Reduced dissolved oxygen concentrations Direct toxicity to aquatic life |

Site selection Options for disposing of effluents Farm design Effluent disposal system Operational management Feed management Waste treatment system |

|

Medium |

Impact of chemicals and therapeutants on receiving waters |

Site Selection Quality of water supply Farm design Disinfection system Operational management Stock management procedures Health checks Minimise risks of accidents and spills | |

|

Impacts of filter sludge Note: Not an issue for farms discharging to sewer systems |

Medium–High |

Nutrient enrichment resulting from nitrogen and phosphorous in effluents Increased water turbidity and sedimentation Reduced dissolved oxygen concentration Direct toxicity to aquatic life |

Site Selection Geology and soils Farm design Sludge management systems. Operational management Feed management. Wastewater treatment system |

|

Impacts of mortalities and processing wastes |

High |

Contamination of surface and groundwater Direct toxicity to aquatic life |

Site Selection Geology and soils. Farm design Disinfection system Fish waste disposal system Operational management Animal husbandry procedures Stock health management |

Disposal of filter sludge

Filter sludge is similar in composition to liquid effluent but can be more damaging to the environment because the components, suspended solids, oxygen-consuming wastes and nutrients, are more concentrated. While some RAS managers combine filter sludge with liquid effluents prior to discharge, it is more common to concentrate sludge by allowing it to settle in ponds or sumps and subsequently dispose of it by burial or other means.

Improperly constructed settlement ponds and disposal pits may leak and pollute surface and ground water resources. Potential impacts from sludge wastes reaching surface waters on water and sediment quality are similar to those documented for effluent.

The least risky option for disposing of sludge is by discharge to municipal sewer. Other disposal options are riskier and require additional treatment or transfer of sludge to another location.

Disposal of mortalities and processing wastes

Mortalities and processing wastes that are improperly disposed of can have a significant negative impact on the environment. Disposal of this material is often by on-site burial in pits. If improperly designed and maintained, pits can be a source of groundwater or surface water contamination.

Impacts on native flora and fauna

Impacts on native flora and fauna can occur during RAS construction and or operation. Three main areas of concern with respect to native flora and fauna are identified:

- removal of habitat during construction;

- alteration of habitats through RAS construction and operation; and

- interaction of stock with native fish populations.

Table 7 summarises these concerns and their priority for the RAS industry. Management actions that will minimise impacts are detailed elsewhere in this document.

Removal or disturbance of habitat during construction

Native flora and fauna habitats can be destroyed by excavation or land disturbance during construction of buildings, dams or ponds and associated facilities such as access ways or parking areas (DPI 2005). Clearing native flora or draining of wetlands can significantly impact the biodiversity of flora and fauna, particularly threatened or endangered species. This risk will be moderate to high with the construction of new RASs at undeveloped sites. The severity of impact will depend on the sensitivity of the site and the care taken during construction.

Table 7: Issues related to impacts of RAS on flora and fauna.

|

Category |

Priority for RAS |

Specific Issue |

Refer to specified section in Best Practice Environmental Management |

|

Destruction or alteration of habitats |

Moderate–High |

Habitat destruction during construction |

Site selection Environmental sensitivity Farm design Impacts on flora and fauna |

|

Moderate |

Alteration of habitat through construction and operation |

Site selection Access to water Farm design Construction Water source Operational management Water management | |

|

Interactions with birds and mammals. |

Low |

Fish-eating birds and mammals harass or consume stock or pollute aquatic environment of RAS |

Note: RASs, by their design exclude birds and mammals Farm design Prevention of birds and mammals entering facility Biosecurity |

|

Interactions with native fish |

Low |

Escape of non-native species |

Note: RASs, by their design, do not generally allow fish to escape Farm design Prevention of fish escapes Biosecurity |

|

Disease transmission to native species |

Farm design Biosecurity Operational management Disinfection | ||

|

Impacts of hormones or bio-actives on native fish |

NA |

Alteration of habitats through RAS construction and operation

The main issues related to the alteration of habitats during RAS construction and operation relate to the ecological consequences of modifications in water and sediment quality.

Construction

Ecological impacts during construction may arise from the disturbance of riparian vegetation which can increase erosion rates and affect the hydrology of local rivers. Increasing erosion and sedimentation can result in a general deterioration of water quality and potentially smother aquatic habitats.

Water extraction

Water flow to and from aquaculture facilities can affect natural stream hydrology, alter stream flows, increase river bank erosion and impact water quality including raising turbidity. These changes can significantly impact the habitat of resident native flora and fauna.

Depending upon the efforts undertaken to minimise impacts during facility construction, this risk will be moderate to high. Once a RAS is completed and filled, ongoing water requirement is generally limited to the relatively small amount required to makeup water lost to leakage, evaporation and waste disposal.

Interactions with native fish populations

Non-endemic pathogens and parasites can be transferred to local species by direct contact with escaped stock or indirectly via effluent.

Escaped stock can prey on or compete with native fish for limited resources. If large numbers of fish escape, possible genetic effects must be considered. To minimise the risks of interactions with native fish populations, translocations of aquatic animals to RASs should be in accordance with the Victorian Protocol for the Translocation of Aquatic Animals to Recirculating Aquaculture Systems (DPI 2008).

Improper burial of mortalities on-site is a potential source of infection for farm and wild stocks.

Impacts on humans in terms of nuisance or risks to health

The impacts on humans from RAS can be divided into three categories:

- noise;

- visual impacts; and

- odour.

Table 8 summarises these issues and their priority for the RAS industry. Management actions to minimise these impacts are detailed in the relevant sections in the Best Practice Environmental Management chapters.

Noise

Noise impacts are generally relevant if the RAS is located near residences or where it will impact on other users of a resource. Nuisance noise from aquaculture facilities is usually caused by continuously running mechanical equipment such as pumps and aerators. Intermittent noise can result from construction activities, use of heavy vehicles for transporting stock and feed and equipment used to scare predatory birds.

Visual impacts

The visual impacts of RASs are usually not significant as most blend in well with the agricultural landscape. Low-profile buildings and enclosed equipment negates many of the visual impacts of other forms of aquaculture.

Odours

Unpleasant odours from aquaculture facilities can result from solid organic waste, mortalities and from the by-products of processing that are not properly disposed of.

The potential for fish farm wastes to become a odour issue can be reduced by following the procedures outlined in subsequent sections of this document.

Table8: Issues related to impacts on humans.

|

Category |

Priority for RAS |

Specific Issue |

Refer to specified section in Best Practice Environmental Management |

|

Visual Impacts |

Low |

Farm facilities and general rubbish may provide visual intrusion. |

Reducing visual impacts |

|

Noise |

Low |

Mechanical equipment, transport vehicles and predator prevention equipment can cause noise. |

Reducing noise |

|

Odour |

Low |

Improper disposal of wastes may result in odours. |

Reducing odours |

Impacts on the wider global environment

Impacts on the global environment can influence how the industry is perceived by the wider community.

Selection of fish diets

Feed is the major input to many aquaculture systems. The quality and quantity of the diet and efficiency with which it is fed to and digested by stock are the most important factors that establish the quality of effluent and sludge wastes in aquaculture systems.

An important issue for the global aquaculture industry is its apparent dependence on fishmeal-based diets. Fish meal is produced from stocks of wild-caught fish, a number of which are classified as fully exploited, over-exploited or depleted (Naylor et al. 2000; FAO 2002). Consequently, stock depletion is regularly cited as a negative impact of the aquaculture industry.

The finite availability of fishmeal is seen as a major constraint to international aquaculture development and industry and feed manufacturers have worked to find replacement ingredients for over 20 years. Australian manufacturers replace fishmeal with vegetable materials and most feed manufacturers require fish meal and fish oil supplies be sourced only from managed and sustainable fisheries.

Industry should continue to work with feed manufacturers to develop cost-effective alternatives to fishmeal-based diets and purchase feed from companies that demonstrate an environmentally sustainable approach to the formulation of their diets and the source of the ingredients.

Greenhouse gas emissions

Recirculating aquaculture systems often heat and or cool water to optimise growth rates. Efficient use of energy is important in reducing costs for the site and the amounts of greenhouse gases that are directly and indirectly released through the burning of fossil fuels to operate machinery, pumps and other equipment.

Greenhouse gas emissions can be minimised by using gravity flow where possible and insulated buildings to conserve heat energy. Maximising the percentage of water recirculated within the RAS will further reduce heating requirements. The use of energy-efficient equipment and off-peak electric supplies will further reduce energy consumption.

Best practice environmental management: site selection, farm design and construction

An essential requirement of RAS BPEM is compliance with relevant regulatory requirements. When applied during the site selection, farm design and construction stages, they allow developers to mitigate potential impacts and make the adoption of the principles of cleaner production easier and less expensive.

In this section, general guidance on matters to consider during site selection, farm design and construction is provided. This guidance is based on the experience of the project team and codes of practice from other states (e.g. Donovan 1999).

Site selection

In aquaculture there is a clear relationship between physical and biological characteristics of sites and the economic and environmental costs associated with developing a project. Although the enclosed nature of RASs does reduce the importance of some physical site features, the selection of a suitable site is of critical importance in the development of a RAS operation.

Major issues that must be considered during the site selection process are:

- location;

- environmental sensitivity of the site;

- climatic factors;

- site topography, geology and soils;

- access to water;

- quality of water supply; and

- available options for effluent disposal.

Location

The most suitable areas for RAS development are rural zones and industrial zones and applications to develop RASs in these zones may require a less rigorous approvals process. In some rural zones (i.e. Farming and Rural Activity zones), a permit is not required for aquaculture development.

Selection of an appropriate site should consider the proximity to residential or other areas that may be sensitive to noise or aesthetic considerations. Other factors such as the proximity of the site to major roads, transport, markets and population centres should be considered during planning.

Environmental sensitivity of the site

The site and adjacent areas should be assessed for environmental values such as sensitive flora and fauna habitats and areas of cultural heritage. Sensitive or protected areas, which could be impacted by construction activities and farm operations, should be avoided if possible. Authorisations to remove native vegetation, drain wetlands and conduct earthworks must be obtained from relevant agencies before undertaking work.

Climatic factors

Climate does not generally limit production in RASs as the aquatic environment can be controlled. Selection of sites where the climate approximates the requirements of the cultured species can reduce heating and cooling costs.

Site topography, geology and soils

Where a proposed aquaculture site is vulnerable to flooding the proposed site should be situated above 1-in-100 year flood level to reduce the risk of inundation.

Topography conducive to using gravity for influent and effluent flow and operation of ponds and irrigation systems can reduce pumping costs. Appropriate topography may facilitate construction of storage dams if required.

If dams will be constructed, the water-retaining properties of associated soils, the presence of contaminants should be determined and the risks of contaminating groundwater from effluent or waste disposal must be considered.

Water supply

While the enclosed nature of RAS provides isolation from the environment, a key risk to systems is that the quantity and quality of the water supply to the system will be inadequate. During site selection, RAS developers must consider existing and potential water supply issues including housing and industry development and the potential effects of climate change.

Water sources include municipal supplies, groundwater and surface waters. An appropriate authorisation issued under the Water Act 1989 may be required.

Municipal suppliers provide a consistent supply of high quality water but often disinfect water with chemicals that can kill stock and the beneficial bacteria in biofilter systems.

Surface water supplies may exhibit seasonal variations in temperature and quality related to climatic factors and rainfall (e.g. silt loadings). Surface water quality can be affected by upstream pollution and, unless appropriately treated prior to use, may be a source of disease and parasites to the farm.

Groundwater obtained from bores offers a more predictable source of water but is often deoxygenated and can contain elevated levels of metals, particularly iron. Murray cod produced using groundwater have suffered from chronic erosive disease syndrome, the cause of which is unknown but may be related to the ionic composition of the water.

Prior to RAS development, water sources should be assessed against ANZECC guidelines (Appendix B), seasonal variations in supply and quality and the requirements of the cultured species. The potential for pollution including potential upstream pollution sources and impacts of future developments should also be considered.

Options for effluent disposal

Effluent disposal options must be considered during RAS site selection. Discharges greater than 0.2 ML/day to surface waters requires an EPA discharge licence and a works approval is required for smaller volumes. Discharge to surface water is the least preferred option for effluent disposal.

Best practice environmental management requires evaluation of all effluent disposal options including land irrigation, hydroponics and disposal through the mains sewer system. The suitability of effluent disposal via irrigation should be assessed against the Guidelines for Wastewater Irrigation (EPA 1991).

Farm design

Recirculating aquaculture systems should optimise economic viability and minimise impacts on the environment. To achieve best practice environmental management, the following matters should be considered during project design:

- aesthetic values;

- impacts on flora and fauna;

- prevention of fish escapes;

- quantity of water required;

- water source;

- biosecurity;

- water recirculation;

- energy efficiency;

- biological filtration systems;

- mechanical filtration systems;

- dissolved gas systems;

- disinfection systems;

- effluent disposal systems;

- sludge management systems; and

- fish waste disposal systems.

Aesthetic values

Recirculating aquaculture systems can be installed into existing buildings but purpose-built buildings are often constructed. New buildings require additional approvals such as planning permission from the local authority. Building design including size and colour and site maintenance should consider the aesthetic values of the area and the planning requirements of the zone in which the RAS is located.

Impacts on flora and fauna

Ecologically or environmentally sensitive areas should be identified and considered during facility design. Water intake and discharge locations should be selected to minimise impacts on native flora and fauna.

Prevention of fish escapes

The enclosed nature of RAS minimises the risk of fish escape. Additional biosecurity measures including screens of appropriate size on outflow pipes and bunding to contain water spills may be required where a system will be stocked with species that are not established in the catchment or region. Bunding guidelines have been published by the EPA (EPA 1992).

Quantity of water

Sufficient water to fill the system and provide a daily water exchange of 10 to 20 per cent is a general requirement of RAS. Ideally, sufficient water available to completely replace the system volume should be available.

Water source

The quality of influent water dictates the pre-treatment required, is site specific and may exhibit annual fluctuations. Surface water often requires filtration and disinfection or sterilisation before use. Groundwater may require aeration to increase dissolved oxygen concentrations, removal of dissolved gases including nitrogen and hydrogen sulphide and minerals. Municipal supplies may require de-chlorination. To address negative changes in supply and quality, RAS should have appropriate systems including filters, purifiers, disinfection and storage facilities installed.

Biosecurity

Translocations to RASs must be conducted in accordance with the Victorian Protocol for the Translocation of Aquatic Animals to Recirculating Aquaculture Systems (DPI 2008). Where a proposed translocation is not within the scope of the RAS translocation protocol, it must be conducted in accordance with the Guidelines for Assessing Translocation of Live Aquatic Organisms in Victoria (DPI 2003).

Water recirculation

The daily water recirculation level in RASs will often exceed ninety per cent although the amount can vary depending on the availability of water, health of stock and facility management practices. When a large amount of system water is replaced, the water chemistry profile of the make-up water should be similar to the target specie's requirements. The design capacity of an effluent treatment system must meet or exceed the maximum anticipated discharge level from the system. If water discharges exceed 0.2 ML/day, an EPA discharge licence is required.

Energy efficiency

Energy efficient RASs have reduced energy requirements and operational costs. An energy efficient site should maximise water recirculation and use insulated buildings and off-peak electricity if possible. Hydroponic systems that recover lost energy sources (e.g. CO2) may warrant consideration during the RAS design stage.

Use of energy management systems, emerging technologies and alternative energy sources including solar electricity generation and heating may further reduce energy consumption.

Biological filtration systems

Loads to biological filters are primarily a function of feeding rate and stock biomass. As stock grow and feed inputs increase, biological filter loads can increase. Effective biological filtration systems efficiently convert ammonia and nitrite to nitrate across the range of biomass and feed input levels (Hutchison et al. 2004).

Mechanical filtration systems

Mechanical filtration removes up to 80 per cent of the suspended solids (e.g. faeces, uneaten food) from the water stream. Removal of suspended solids reduces blocking and fouling of the biofilter; ensures a stable population of bacteria and efficient biofilter operation; reduces levels of water-borne bacteria; and makes biofiltration and disinfection systems including ultraviolet light and ozone more efficient.

Dissolved gas systems

Criteria for assessing dissolved gas systems include site design, target species and the stocking densities. Dissolved gas systems should, across the range of expected biomass and food input levels, maintain dissolved oxygen concentrations at levels appropriate for the cultured species and the biological filter.

Disinfection systems

Disinfection systems including ultraviolet light and ozone destroy pathogens in incoming and system water and effluent. In designing disinfection systems, care must be taken to ensure biofiltration systems are not affected.

Effluent disposal systems

Effluent disposal systems should minimise impacts on the aquatic environment. Effluent discharged directly to surface waters is the least preferred disposal option. Pre-treatment using a settlement pond will reduce the quantity of suspended solids in the effluent stream but must not impact on groundwater.

In the event of a complete and rapid water exchange, effluent disposal systems should have the capacity to store or process the entire RAS volume.

Irrigation with wastewater should be conducted in accordance with EPA guidelines (EPA 1991).

Sludge management systems

Options for sludge disposal should be considered in accordance with EPA guidelines. The most common method of sludge disposal is combining it with liquid effluent and transferral to municipal wastewater treatment facilities.

Although pit disposal has been used, this method of disposal is not preferred by the EPA. Pits or ponds for sludge disposal, de-watering or stabilisation should be designed by an qualified practitioner and should not leach into groundwater supplies or overflow during floods. Disposal to appropriate landfill sites should be considered.

Fish waste disposal systems

Above-ground composting is a low-cost method for on-site disposal of mortalities and processing wastes (DPI 2006). Where land suitable for composting is not available, disposal to suitable landfill sites should be considered.

Construction

Construction should only occur within the work site and controls to minimise off-site impacts should be implemented. Removal of native vegetation should only be undertaken with appropriate authorisation. Measures should be taken to limit the impacts that construction and operation of an aquaculture venture on native flora and fauna.

Bunds and vegetative buffers can stabilise topsoil and reduce erosion and silting of waterways. Water intake and effluent discharge equipment should be located to minimise disturbance and impacts on aquatic and riparian vegetation. To reduce the impact on the local river or stream system, alternative water sources such as ground water or town supplies should be investigated (DPI 2003b). Similarly, alternative discharge methods such as local sewer systems, treatment plants or as potential irrigation sources should be considered.

Best practice environmental management: operational management

Operational management is the day-to-day work practices required to manage RASs. Although common to most RAS facilities, management practices vary between facilities and are influenced by the species produced and the intensity at which the system is operated.

In the context of this BPEMG, the goal of operational management is to maintain stable conditions that optimise fish growth and survival. An unstable system with sub-optimal culture conditions will increase the production of waste streams and adversely impact the environment.

The main operational procedures conducted by RAS managers relate to:

- environmental management;

- stock management;

- feed management;

- health management; and

- waste management.

Environmental management

Species exhibit optimal performance within a limited range of environmental conditions, e.g. temperature. Environmental requirements may be species-specific and constant or change over the life of the animal. Regular monitoring of key environmental parameters is required to address water quality issues promptly.

If stock are held in conditions outside of their optimal range, the impacts on them include:

- cessation of feeding resulting in increased solid and soluble wastes;

- increased susceptibility to disease; and

- increased mortalities.

Maintenance of optimal environmental conditions is assisted by biological and mechanical filters and aeration systems that are appropriate for the level of feed input and stock biomass. Where mechanical and biological filtration, management practices and aeration systems are not sufficient to maintain optimal environmental conditions, increased water exchange is required.

The use of chemicals can assist in managing some parameters, e.g. using lime to buffer pH. Prompt removal of solid wastes from the system will reduces the load on the filtration and aeration systems.

Stock management

Effective stock management minimises stress on stock and optimises production. Fish should be handled carefully and appropriate anaesthesia used if required.

Inspection and quarantine

Before stocking fish to RAS, they should be quarantined, checked for disease and treated accordingly. Stock should be purchased from a reputable supplier with a record of supplying healthy fish.

To lower the risk of cross-contamination, new stock should be quarantined or held separate from resident stock for at least three weeks after arrival. Quarantine or separation involves maintaining stock in individual growing units, using dedicated equipment (e.g. nets, cleaning equipment) and controlling access by personnel.

Stocking and grading

Fish should be stocked at densities appropriate for the species. Murray cod and eels tolerate stocking densities in excess of 100 kg/m3 and may tolerate lower or higher densities.

Most fish species exhibit hierarchical feeding patterns that result in some fish receiving less food than others. Over time, this will cause large size differences within the population that can exacerbate cannibalism and complicate the calculation of feeding levels and harvest biomass. Regularly grading stock into similar size classes is critical to resolving these problems.

Feed management

Feeding rate, feed composition, stock metabolic rate and uneaten feed will impact RAS water quality. Where possible, RAS operators should use commercial diets (i.e. pellets) that are specific for the farmed species or a related species, if unavailable.

Food conversion ratios (FCR) should range from 1.0 to 2.0:1. Feed types and feeding rates should be continuously monitored and appropriate to stock life-stage, water temperature and general appetite. Efficient feeding regimes will reduce feed wastage and cost, labour requirements, loads on filtration systems and improve FCR.

The first-in, first-out system of stock feed rotation ensures stock are fed the freshest feed on hand. Feed should be stored in a cool, dry place that is free of insects and vermin to minimise deterioration and contamination.

One of the most important RAS management tools is the ability to feed fish to satiation without overfeeding. The amount fish are fed is usually calculated as a percentage of body weight or culture unit biomass per day and is inversely proportional to the size of the fish. When stock are held within their optimal temperature range, food consumption increases with rising temperature.

Feeding charts indicating the appropriate feeding rates for different life stages of the commercially important aquaculture species and feed types are available from some feed manufacturers. Because feeding charts are not available for most native species, RAS managers should maintain feeding records to assist in feed management decisions.

Prompt removal of uneaten feed from RASs will reduce the solid waste and nutrient loads on filtration systems assist in maintaining acceptable levels of water quality.

Health management

Maintaining an optimum environment, including meeting the nutritional requirements of stock is a fundamental requirement of RASs. Optimal environments reduce stress and the incidence of illness in stock.

Several exotic and ubiquitous organisms including viruses, bacteria, fungi, protozoa, crustaceans, flatworms, roundworms and segmented worms cause disease and or parasitise in aquaculture stock. Organisms can enter RASs in water supplies, with the water used to transport stock from other farms, on stock, on equipment, and in feeds.

Disease outbreaks are a significant constraint to aquaculture production and economic viability. Where intensification of the culture conditions and densities of fish are increased, the spread of diseases is often rapid and can be devastating. To minimise the risks of disease outbreaks, translocations of aquatic animals to RASs should be in accordance with the Victorian Protocol for the Translocation of Aquatic Animals to Recirculating Aquaculture Systems (DPI 2008).

It is imperative that managers plan for disease outbreaks and develop sound health management strategies to reduce the incidence and severity of disease outbreaks. Diseases may progress very rapidly in a RAS, so management strategies should be prepared and updated regularly. Farmers should be familiar with the common diseases and conditions that affect stock health and well-being (Ingram et al. 2005). Staff should be trained to identify sub-standard health conditions and to respond rapidly with appropriate treatment.

Having separate equipment for different areas or tanks of a RAS will help prevent cross-contamination by diseases or parasites. If it is impractical to maintain separate sets of equipment, equipment should be sterilised before movement between areas or tanks.

Waste management

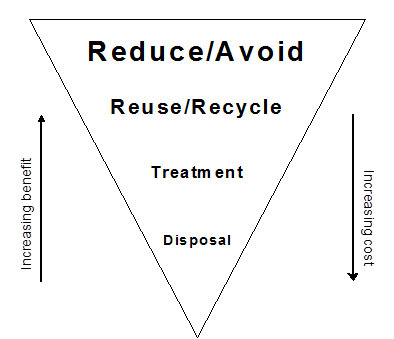

Wastes from aquaculture operations can have significant negative impacts on the environment. Appropriate waste minimisation strategies reduce environmental impacts and ensure the long-term viability of the farm site. Operational impacts of a RAS are largely related to the waste streams identified earlier and may be addressed using the waste management hierarchy (Figure 2).

Figure 2. Waste management hierarchy.

The waste management hierarchy

The Industrial Waste Management Policy (Waste Minimisation) 1990 (Environment Protection Act 1970, section 1 (1I and 1J) reprint 14, July 2002 or later), sets out the following hierarchy of industrial waste management options:

- waste avoidance/reduction;

- re-use, recycling and reclamation;

- waste treatment; and

- waste disposal.

Best practice environmental management ensures that RASs operate at maximum efficiency so that wastes are minimised and re-used in accordance with the waste management hierarchy.

Waste streams during RAS operation were identified and prioritised in the previous section and include:

- sludge from filters and sediment ponds;

- fish mortalities and processing wastes;

- energy and greenhouse gas emissions;

- organic matter and nutrients in effluents; and

- chemicals and therapeutants.

These waste streams are considered with reference to the waste management hierarchy (Table 9).

Fish escapes were not considered as a major issue for RAS.

Table 9: Waste streams from RAS considered with reference to the waste management hierarchy.

|

Waste stream |

Avoidance/ reduction |

Re-use/ recycle |

Treatment |

Disposal |

|

Sludge from filters and settlement ponds |

√ |

√ |

√ | |

|

Fish mortalities and processing wastes |

√ |

√ |

√ | |

|

Energy and greenhouse gases |

√ |

√ |

||

|

Organic matter and nutrients in effluents |

√ |

√ |

√ |

√ |

|

Chemicals and therapeutants |

√ |

Sludge from filters and settlement ponds

Solid produced during RAS operation are continually removed by mechanical filtration. Where effluent is stored in a settlement pond, settled solids must be periodically removed.

Farmers should endeavour to avoid solid waste production in RAS through improved operational management particularly regarding feed.

Options for re-using and recycling solid wastes generated in RAS include production of crop fertiliser or soil conditioner through composting (EPA 1996; DPI 2006). Disposal of the waste, for example to municipal sewer systems, pits or landfill, is the least preferred option for best practice sludge management.

Processing wastes and fish mortalities

Processing wastes are an inevitable consequence of marketing processed fish and fish mortalities are an unavoidable consequence of aquaculture production. Sustained or large losses can be reduced by management practices which minimise stock stress and the risk of disease outbreaks and that employ procedures to address equipment failure (e.g. pump and aeration equipment).

The traditional options for re-use of fish wastes include (Puglisi 1991):

- human food products (e.g. fish mince);

- feed and fertiliser products (e.g. fishmeal, hydrolysed products, compost); and

- products for niche markets (e.g. skins, heads. frames, scales).