Best Practice Salmonid Aquaculture Industry

Fisheries Management Paper

Fisheries Victoria Report Series No. 25

March 2006

ISSN 1448-1693

ISBN 1 74146 187 1 (internet)

Preferred way to cite this publication:

Department of Primary Industries (2005). Best Practice Environmental Management Guidelines for the Salmonid Aquaculture Industry. Fisheries Victoria Report Series No. 25.

Fiona Gavine, Brendan Larkin, Brett Ingram and Morgan Edwards

Foreword

The salmonid aquaculture industry is a long-established and important contributor to a number of regional th economies in Victoria (e.g. Murrindindi Shire). The Victorian Government is committed to improving the th productivity and environmental sustainability of rural industries such as the aquaculture industry through th its Growing Victoria Together policy (www.growingvictoria.vic.gov.au) and the Victorian Regional

Aquaculture Development Program and the Victorian Agriculture Policy Statements on Aquaculture, 2002. th The Victorian Government also has a commitment to protecting and enhancing water quality in rivers through the Victorian River Health Strategy (Department of Natural Resources and Environment (DNRE), 2002) and the State Environment Protection Policy, Waters of Victoria 2003.

The salmonid aquaculture industry has made substantial gains in environmental management over the last decade and it is pleasing to see that the industry is committed to further improvement. The industry needs to achieve continual improvement in farm management practices, and strive to minimise its impacts on waterways and the broader environment.

These Best Practice Environmental Management Guidelines (BPEMG) are the outcome of a long partnership between industry, the Department of Primary Industries (DPI), the Environmental Protection Authority (EPA) and the Department of Sustainability and Environment (DSE). This BPEMG document has drawn on world's best expertise and integrated this information into a Victorian farming context to assist industry and regulators to improve environmental management in the industry.

This guideline document is not the end of the process, but part of a continuum of improvement. We look forward to improved productivity, a reduced environmental footprint and continued industry growth within sustainable limits.

Peter Appleford

Executive Director

Fisheries Victoria, DPI

Mick Bourke

Chairman

Environmental Protection

Authority

Edward Meggitt

President

Victorian Trout Association

Acknowledgments

This document is the product of two separate projects to develop Best Practice Environmental Management Guidelines (BPEMG) for the Victorian salmonid aquaculture industry.

In 1998, the Aquaculture Program of the Marine and Freshwater Resources Institute (MAFRI) was sub-contracted by the Environmental Protection Authority (EPA) to prepare a draft BPEMG for the freshwater salmonid industry in Victoria. The Healthy Waterways Program of the Department of Natural Resources and Environment (DNRE, now Department of Sustainability and Environment) funded this project. The project team consisted of Brett Ingram of MAFRI, Dr Liam Kelly, Heriot- Watt University, Scotland and Dr Simon Cripps, Rogaland Research, Norway. The Steering Committee for the project consisted of representatives from the EPA, DNRE (including The Victorian Fisheries Authority), Goulburn Murray Water and the Victorian Trout Association (VTA). Although the project team completed a draft BPEMG document, industry and EPA failed to reach a consensus on the scope and content of the guidelines and they were not formally adopted. The critical issue in the failure of the last BPEMG was the prescriptive nature of the final draft, which was at odds with the voluntary and non-prescriptive document that was originally intended.

In 2003, Fisheries Victoria took the lead role in resurrecting the project and commissioned the Aquaculture Section of Primary Industries Research Victoria (PIRVic) to implement it. A small Steering Committee with representatives from EPA, VTA and Fisheries Victoria was formed.

As a starting point the EPA and industry agreed that the BPEMG should remain as a reference document. The aim of the new project was to review, redefine and update the draft BPEMG for formal adoption by the salmonid aquaculture industry and government agencies.

The project team would like to thank Victorian trout farmers for their assistance in conducting the industry audit and the feedback provided on various drafts of this document. In particular, Edward Meggitt of the Victorian Trout Association played a key role in conveying the opinions of the industry to the project team. The contribution of Goulburn Murray Water, Goulburn-Broken Catchment Management Authority, EPA and The Victorian Fisheries Authority in providing comment and guidance is gratefully acknowledged.

Executive Summary

The freshwater salmonid aquaculture industry is an important part of the Victorian aquaculture industry for over 20 years and produces juvenile Afish for restocking rivers as well as market-sized Afish for human consumption. There have been concerns that effluent and other waste streams from salmonid aquaculture can have an impact on the environment in which the farms are located. Salmonid farms are reliant on high quality water and tend to be located in relatively pristine environments. It is important for industry to demonstrate to the wider community that it takes its environmental performance seriously and is operating in a responsible and sustainable manner.

The salmonid aquaculture industry is acutely aware of the environmental issues and community concerns related to the industry. Thus industry is eager to demonstrate that it can produce positive environmental outcomes. There is a heightened awareness at all levels of the industry of the importance of environmental management, as well as the potential improvements in production efficiencies and sustainability that can be made Athrough adopting sustainable practices. The development of BPEMG for the salmonid aquaculture sector will provide a tangible mechanism through which the industry can demonstrate its environmental credentials to the community and continue to grow and improve in the future. These guidelines clearly define best practice environmental management for the Victorian salmonid industry. The guidelines will assist existing industry to develop programs, systems and practices to improve their environmental performance in an affordable, sustainable and efficient way.

A comprehensive survey of the Victorian salmonid industry revealed that the industry currently produces five species: rainbow trout (Oncorhynchus mykiss); brown trout (Salmo trutta); chinook salmon (O. tshawytscha); brook trout (Salvelinus fontinalis); and Atlantic salmon (Salmo salar). There are 22 operational farms, 12 of which are located on the Upper Goulburn system and its tributaries in the north-east of the state. Infrastructure components on Victorian salmonid farms commonly include hatcheries, production units (ponds and raceways), wastewater treatment systems and processing units. Principal inputs to salmonid culture were identified as fish, water, feeds and chemicals and therapeutants.

The waste streams from salmonid culture were identified as the most important source of environmental impacts and provided the basis for development of the BPEMG. Waste streams were identified as:

- organic matter (mainly uneaten feed and fish excreta) in effluent ;

- sludge from settlement ponds;

- chemicals and therapeutants;

- fish mortalities and processing wastes;

- fish escapes; and

- greenhouse gas emissions.

The potential impacts of these waste streams and other farm activities on the aquatic environment, native flora and fauna, humans (in terms of nuisance) and the wider global environment were examined in detail. Best practice measures to reduce and remedy the impacts identified were then documented. .Best practice. was defined in the context of the salmonid aquaculture industry as:

Minimising the waste stream by maximising production efficiency per unit production.

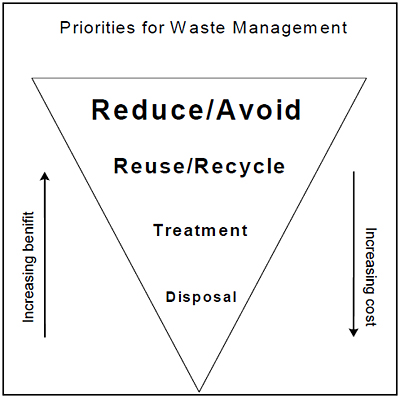

The cornerstone of best practice for all salmonid operations is to comply with all regulatory requirements. Best practice environmental management procedures were developed using the Waste Management Hierarchy where possible to minimise waste streams. In other words, the scope for reducing waste streams through avoidance, recycling or re-using and treatment was analysed so that disposal to the environment was the last resort. Table i shows the waste management hierarchy as it is applied to waste streams from salmonid farming.

Table i: Treatment of waste streams from salmonid aquaculture according to the waste management hierarchy

| Waste stream | Avoidance/ reduction | Re-use/recycle | Treatment | Disposal |

|---|---|---|---|---|

| Organic matter & nutrients in effluent | ||||

| Sludge from settlement ponds | ||||

| Chemicals and therapeutants | ||||

| Fish mortalities and processing wastes | ||||

| Fish escapes | ||||

| Greenhouse gases |

Operational management procedures for other activities that may have environmental impacts were also documented.

Best Practice measures were documented for a range of waste streams:

Organic matter and nutrients in effluent

- Feed management

- Water (oxygen) management

- Use of nutrient mass balance models

- Waste treatment

Settled solids from ponds and treatment facilities

- Minimising sediment production on-farm

- Re-using and recycling of sludge

- Treatment options

- Minimising impacts of disposal

Chemicals and therapeutants

- Minimising the use of chemicals and therapeutants

- Minimising risks of accidents and spills

Fish mortalities and processing wastes

- Reducing mortalities

- Recycling of mortalities and processing wastes (e.g. through composting)

- Disposing of mortalities appropriately and processing wastes

Fish escapes

- Screening of inlet and outlet structures

Greenhouse gas emissions

- Conducting an energy audit and adopting an environmental management plan to reduce energy consumption and increase efficiency

Other environmental issues that could not be addressed using the waste management approach included:

Water abstraction

- Monitoring and managing water flows between inflow and outflow structures

- Employing supplementary aeration or oxygenation to mitigate water demand

- Investigating options for water recycling

Impacts on habitats

- Carrying out all construction with appropriate planning consents

- Receiving an EPA Works Approval for new works

Birds and other predators

- Following guidelines previously developed by the Victorian Trout Association

Visual impacts

- Ensuring litter is kept to a minimum

- Screening site appropriately

Noise

- Muffling noisy machinery

- Complying with EPA country noise guidelines

Odours

- Removing sources of odour quickly

The document also provides guidance on the parameters that should be monitored (in addition to the frequency of monitoring) in order for salmonid farmers to comply with their regulatory responsibilities. This information will allow farmers to monitor the impact of their operations more effectively as well as calculate nutrient mass balance models and oxygen budgets. The use of these two management tools can increase the efficiency with which a farm operates, particularly in terms of feeding efficiency and water management.

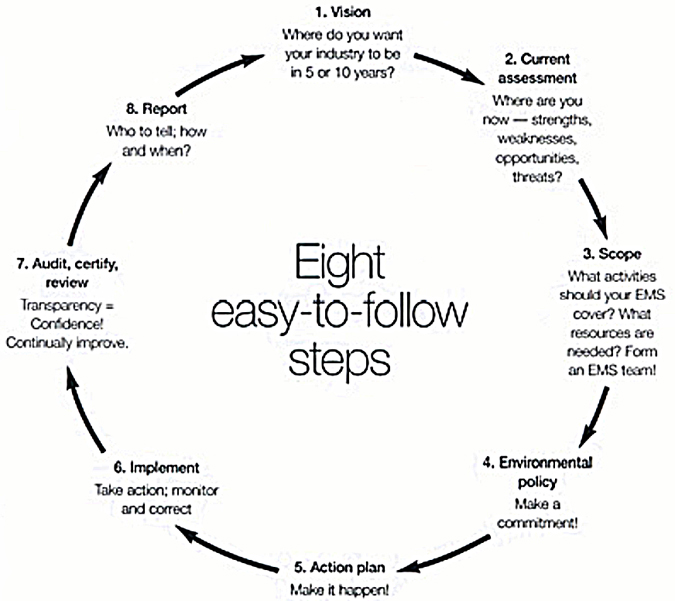

The next logical step for salmonid farmers operating at best practice levels is to prepare a site- level Environmental Management System (EMS).

An Environmental Improvement Plan, a type of EMS, is required from all farmers by the EPA as part of their discharge licence. The final section of these guidelines summarises the key elements of an EMS and provides a step-by-step plan for developing one. It is hoped that the adoption of an EMS will provide a tangible mechanism through which the best practice measures identified in this report can be implemented by industry.

The BPEMG document describes a progressive approach to environmental management issues for the Victorian salmonid industry and builds on steps already taken by the industry to integrate economic and environmental objectives.

Introduction

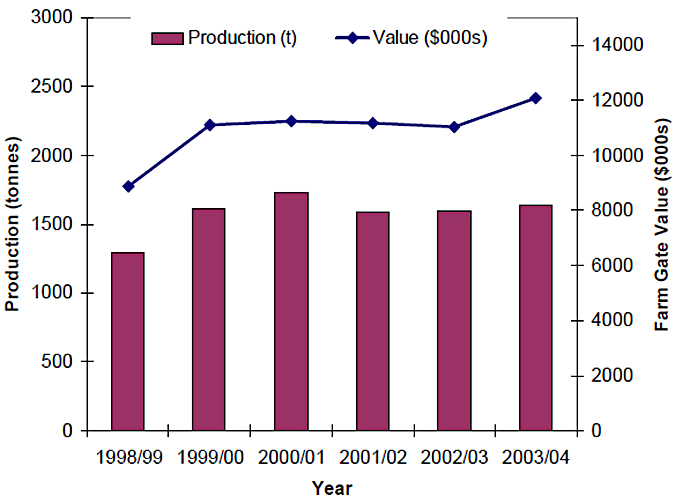

Salmonids are temperate fish and their culture requires access to high quality, relatively cool waters. Salmonid farms are usually located in the headwaters of river systems, or in the upper reaches of regulated rivers where the thermal regime and water flow is conducive to year-round production. In 2003/2004, Victorian production of market sized freshwater salmonids was around 1,637 tonnes, the industry had a farm-gate value of over $12 million per year (Anon, 2004) and accounted for around 85 percent of the total Australian production (Love and Langenkamp, 2003). On a global scale the Australian industry is very small, with Europe alone producing 400,000 tonnes of salmonids per year. The Victorian industry also produces around 0.98 million juveniles for restocking rivers for recreational angling purposes (Love and Langenkamp, 2003).

The salmonid aquaculture industry directly employs around 130 people in rural areas of Victoria (Anon, 2004) and plays a significant role in regional tourism, underpinning the recreational fishing industry in many inland areas of the state. The value of the recreational fishing sector to the Victorian economy has been estimated at around $396 million per year (Henry and Lyle, 2003).

Inland waters in Victoria are lifelines for rural communities and support a variety of agricultural industries and domestic water supplies, as well as being valuable environmental, recreational and aesthetic assets. In recent years, there has been increasing awareness about the need to protect water quality in inland waterways so that they can continue to sustain the ecological values, communities and industries that rely on them. The Victorian Government is committed to achieving healthy waterways through the Victorian River Health Strategy (DNRE, 2002). Indeed, the state environmental protection policy (Waters of Victoria) and its schedules stipulate a number of beneficial uses of surface waters (including aquaculture) that communities want to protect (Victorian Government Gazette, 2003).

Concerns have been raised about the impact of effluent from salmonid aquaculture on the aquatic environment, particularly the potential of nutrients and organic matter in aquaculture wastes to add to other catchment sources of pollution and cause the deterioration of water quality. Nutrients, particularly nitrogen (N) and phosphorus (P) are discharged in effluent from salmonid aquaculture under Environmental Protection uthority (EPA) discharge licences. The EPA is particularly concerned about the impact of nutrients on localised waterway reaches and wants to ensure that beneficial uses of that waterway are adequately protected. Catchment Management Authorities (CMA) in Victoria are actively trying to reduce nutrient loadings from all sources on a catchment basis and, as a result, some have placed a limit on the amount of P that can be discharged. For example, the Goulburn-Broken CMA imposed a P limit of 28.6 tonnes per year on the industry in 1998, based on 1993/94 production data and the use of mass-balance models to calculate P loads from the industry (Ingram, 1999).

The salmonid aquaculture industry has made considerable improvements in environmental management since the benchmarking study in 1993.94 (Ingram, 1999), particularly in terms of nutrient levels in effluent which have been substantially reduced (according to mass-balance estimates) through using higher quality feeds and feeding more efficiently. There is a heightened awareness at all levels within the industry of the importance of environmental management and the potential improvements in production efficiencies that can be made through minimising waste at site level.

The development of Best Practice Environmental Management Guidelines (BPEMG) for the salmonid aquaculture sector will provide a tangible mechanism through which the industry can demonstrate its environmental credentials and continue to grow and improve in the future. Specifically, BPEMG have the potential to offer the following advantages to the salmonid aquaculture industry (Seafood Services Australia, 2002):

- improve economic efficiency through reducing waste at site level;

- demonstrate that organisations within the industry recognise relevant environmental issues and use natural resources in a responsible and sustainable way;

- consolidate good relationships with local communities through perception of industry.s commitment to good environmental performance;

- secure and maintain access to markets, particularly export markets; and

- demonstrate compliance with relevant legislation and regulations.

Objectives of the BPEMG

These guidelines will clearly define best practice environmental management for the Victorian salmonid industry and promote a greater understanding within the industry of the environmental context in which it operates. The guidelines will assist existing industry to develop programs, systems and practices to improve their environmental performance in an affordable, sustainable and efficient way, but recognise that retro-fitting technologies to existing farms may not always be practical or cost-effective. New entrants to the industry will be expected to adopt best practice from the outset.

The guidelines will benchmark existing practices, identify the main environmental issues associated with the industry and outline methods by which impacts may be minimised. A framework for environmental improvement will be developed for the industry, which could be used by individual operators to develop site specific Environmental Improvement Plans (EIP) or Environmental Management Systems (EMS). Specifically, these guidelines will provide information on:

- salmonid farming practices in Victoria including principal inputs and wastes generated, to benchmark current practices;

- the regulatory environment under which the salmonid industry operates;

- potential environmental issues related to the salmonid industry. This section will identify potential impacts of the salmonid industry on the environment as well as the risks to the industry from the environment;

- BPEMG for the salmonid industry detailing measures that will reduce environmental impacts; and

- developing an Environmental Management Systems (including an EIP) for an organisation.

Several appendices are included in this document:

- Appendix 1 contains water quality guidelines for aquaculture production;

- Appendix 2 details the SEPP water quality objectives for rivers and streams in Victoria;

- Appendix 3 considers environmental issues that can be addressed during facility site selection, design and construction; and

- Appendix 4 lists the acronyms and abbreviations used in this document.

These guidelines are intended for use by salmonid farm operators (i.e. producers holding an Aquaculture (Private Land- Salmonids) Licence issued under the Fisheries Act 1995) that produce aquatic products for commercial purposes. This BPEMG is intended solely as a reference document and not as a regulatory instrument or as a basis for approvals, licences or permits. It aims to promote a greater understanding of the diverse environmental considerations required by government agencies that need to be addressed by the salmonid industry.

Freshwater salmonid industry in Victoria

Salmonids are not indigenous to Australia and were first introduced to Victoria in 1864 as part of a massive effort to acclimatise new plant and animal species to the growing colony (Clements, 1988). Early colonists valued salmonids for their sport fishing attributes as well as their nutritional value and these species are considered a valuable part of Victorian heritage. Salmonids were initially introduced to the cooler areas of the state (outside of the Murray River Basin) that generally had a poor selection of indigenous fish of interest to the angler or consumer (Clements, 1988).

The breeding of salmonids for stocking has been undertaken by private organisations and the State Government since their introduction and continues to this day. Between April and October each year, The Victorian Fisheries Authority releases between 300,000 and 400,000 salmonids into Victoria's public waterways. The commercial salmonid aquaculture industry in Victoria developed during the 1970s and 1980s and grows fish for human consumption as well as providing juveniles and advanced fish for restocking.

In 2003/2004, there were 29 operators holding a licence to culture salmonids with 22 farms currently producing stock (Anon, 2004). A confidential survey of the 22 operating farms was carried out in 2003 as part of the BPEMG and the results are summarised below. The results of a similar study carried out in 1998 are included for comparison.

Size, location and distribution

The Victorian salmonid industry produces five species: rainbow trout (Oncorhynchus mykiss); brown trout (Salmo trutta); chinook salmon (O. tshawytscha); brook trout (Salvelinus fontinalis); and Atlantic salmon (Salmo salar). Brown trout and chinook salmon are produced predominantly for re-stocking, whilst Atlantic salmon are grown to produce high quality caviar and flesh. Rainbow trout are the main species grown for human consumption (and are produced for re-stocking) and comprise over 95 percent of Victorian salmonid production. About 70 percent of farms are producing table sized fish (live, freshly gutted, filleted or smoked) but most also have other income streams from the sale of fertilised eggs, juveniles, value-added products (caviar, smoked fish, patè) or tourism (including fish-outs). Four farms have closed since the previous survey in 1998 and two farms have re-opened.

Figure 1 shows that production from the Victorian aquaculture industry is relatively stable on an annual basis with 1,500 to 2,000 tonnes of table sized fish produced each year. Production tends to decrease during periods of drought as farms lower stocking levels to cope with reduced water supplies and high water temperatures.

Figure 1: Production and value of salmonid aquaculture Ain Victoria during 1998 to 2003

Of the 22 farms producing table-sized salmonids, six (27 percent) are producing over 100 tonne per year, six (27 percent) are producing between 20 to 99 tonnes. Ten farms (45 percent) are producing less than 6 tonnes per year, with some fish-outs producing less than 1 tonne. In 2003, 42 percent of farms surveyed indicated that they had increased production over the last five years. The gains in production occurred mainly from the larger farms. Generally production at the smaller farms, and those involved in tourism (e.g. fish-outs), had remained relatively static, while a smaller percentage had decreased production over the last five-year period.

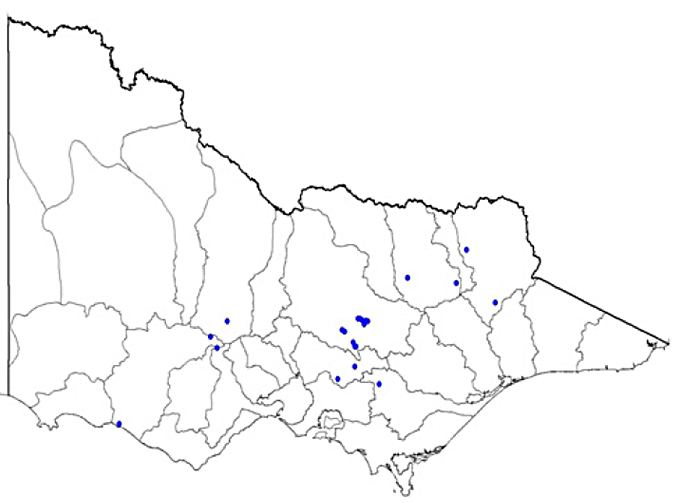

Twelve farms representing 85 percent of total production in tonnes in 2003 are located on tributaries of the upper Goulburn River system. The remaining farms are located within the upper catchments of the upper Murray River and Mitta Mitta River, Ovens River, Loddon River, La Trobe River and the Yarra River. Seventeen farms are situated on river drainages which flow into the Murray River system north of the Great Dividing Range. The remaining farms are located on coastal drainage systems south of the Great Dividing Range (Figure 2).

Figure 2: Location of Victorian salmonid farms in 2003

Farming systems

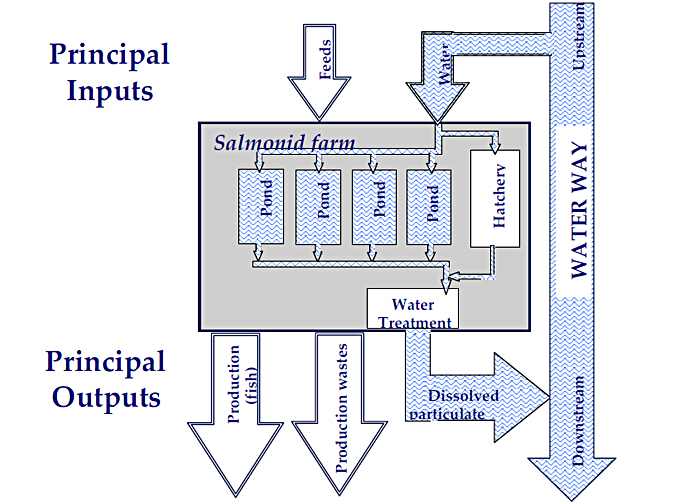

Freshwater salmonid farming requires a continual supply of relatively clean, cool water which is usually abstracted from an adjacent waterway, passed through the aquaculture complex and discharged back into the waterway downstream.

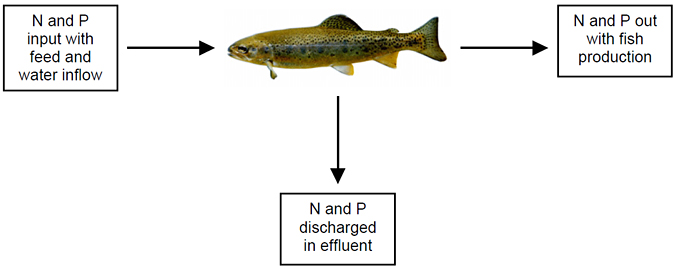

A schematic representation of general system components and the principal inputs and outputs of the farm is shown in Figure 3.

Figure 3: Schematic of a flow- through salmonid farm

Infrastructure components on Victorian salmonid farms commonly include:

- a hatchery;

- production units (e.g. ponds and raceways);

- a wastewater treatment system; and

- a processing facility.

Hatchery

The farming cycle for salmonids begins with the stripping and fertilisation of eggs from farm- reared broodstock during the winter months. The fertilised eggs are transferred first to incubators and then troughs or trays in a hatchery, where they are held in a plentiful supply of well- oxygenated water within an acceptable temperature range.

Once the eggs hatch and the yolk sac is absorbed, the juveniles are weaned onto artificial diets and held in troughs, tanks or specialised small ponds until they weigh about 5 g and are ready to be stocked into production units.

Production units

Two main production units are used for holding and growing fish in the Victorian salmonid industry:

Ponds: Ponds are the most common production units used on Victorian farms and are typically rectangular in shape and of earthen construction. with inlets and outlets positioned at opposite ends. Ponds are generally about 200 to 300 m2 in surface area and have a depth of 1.0 to 1.5 m. They are arranged in series or in parallel with water flowing from one to another by gravity before being discharged.

Raceways: A few farms use concrete raceways, narrow, rectangular structures, where water enters and leaves from opposite ends. With a high rate of water movement, optimal water quality parameters can be maintained allowing fish to be stocked at higher densities than earthen ponds (Masser and Lazur, 1997).

Water treatment system

About 70 percent of farms treat water before discharging it into the waterway from which it was extracted. Farms that do not employ water treatment are generally small production facilities and fish-out operations. A few larger farms are not required to treat wastewater in order to meet their licence conditions.

Wastewater treatment generally involves passing water through a settlement pond or, in a few cases, through a constructed wetland area before discharge. Settlement ponds allow particles to settle out of the water column by reducing horizontal water flow rates. Settlement basin design must consider volume of water to be treated, water velocity and the nature of the particles.

Processing facilities

Sixty- eight percent of farms undertake some processing of fish and had on-site processing facilities. The level of processing varies between farms and includes gutting, gilling and filleting. Some farms conduct further value adding through smoking, producing pates and caviar.

Principal inputs to salmonid culture systems

Fish

About one- half of salmonid farms do not have broodstock and hatchery facilities and must purchase juvenile fish or eggs from other farms. Stocking densities of 10 to 40 kg/m3 are common in intensive farms but less intensive farms stock at far lower densities.

In intensive systems, fish stocks are usually managed for year-round production and the onfarm standing crop (resident stock) represents about 33 to 50 percent of the annual production. Biomass on a farm may vary by as much as 50 percent over the year.

Water

Under intensive conditions, salmonids require continuous water exchange as they have a high oxygen requirement compared with other fish species and are more sensitive to poor water quality (Shepherd and Bromage, 1988). Demand for water (and dissolved oxygen) increases with higher water temperature and is inversely proportional to fish size. The Victorian salmonid industry diverted between 390 to 630 ML/day in 2003; an average of 0.35 ML/day is required to produce one tonne of product per year (range 0.2 to 0.8 ML/day). This ratio, where annual production in tonnes is approximately three times the daily water inflow in megalitres, is a .rule of thumb. adopted by traditional salmonid farms to estimate carrying capacity.

Adopting new technologies can allow farmers to increase production while using the same volume of water. For example, water requirements of salmonids can be lowered by artificially raising dissolved oxygen levels in the inflowing water and by water re-use. To increase oxygen levels, many farms employ passive aerators (e.g. waterfalls located between raceways or ponds) and or mechanical aerators such as paddlewheels and diffusers. Two Victorian salmonid farms use oxygen injection systems to increase the carrying capacity of their production systems especially during warm weather.

The majority of farms (90 percent) partially re-use the water diverted through their facilities. This may involve passing water through more than one pond or pumping a proportion of the effluent water back through the pond system (usually without any form of water conditioning before reuse).

Salmonids have a limited range of ideal environmental conditions. Optimal performance is highly sensitive to water quality including toxins such as dissolved metals present in water. Guidelines on the quality of water required for aquaculture production are detailed in Appendix 1.

Feeds and feeding

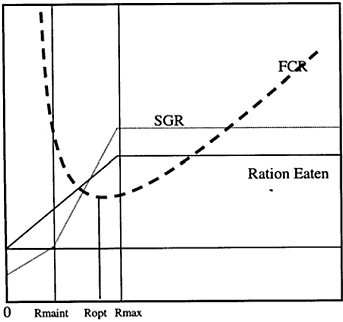

Feed costs can represent over 40 percent of total production costs on fish farms and feed is the major component of nutrient wastes from aquaculture. It is important that fish are fed the appropriate diet efficiently to minimise environmental impacts and ensure economic viability. The fundamental measure of feeding efficiency is the Food Conversion Ratio (FCR)1.

Hand feeding several times a day is the feeding technique used by the majority of salmonid farms with a limited amount of mechanised or automated feeding systems also in use. The importance of feed management to Best Practice Environmental Management (BPEM) in salmonid farming is considered in detail later in this report.

Historically, salmonid feeds were trash fish and raw offal products. Early manufactured diets were steam-pressed pellets produced by livestock feed manufacturers. These diets were characterised by low energy levels (8 to 12 percent) with high levels of indigestible carbohydrates used to aid pellet binding.

These low energy diets were dusty, had low water stability and generally resulted in much higher FCR than today.s diets. The steam-pressed ration used by the Victorian trout industry in 1998 had an industry-wide FCR of 2.05:1 (Ingram, 1999).

1 FCR = weight of dry food fed to fish : wet weight gain of fish flesh

Advances in technology and the understanding of salmonid physiology have led to the development of high-energy extruded feeds that are more stable, less dusty, highly digestible and have a much higher energy level (due to a higher level of oils). Commercially available high-energy extruded diets have protein levels of about 40 to 45 percent and energy levels of 22 to 28 percent. Whole-farm FCR range between 1.0:1 and 1.3:1.

Two companies are the main suppliers of salmonid diets to the Victorian industry and in recent years both have worked with industry to refine the quality and composition of their products. This has resulted in marked improvements to the efficiency with which diets are fed and the quality of the diets available.

A major difference between the 1998 and 2003 is the drop in the number of farmers sieving feed prior to feeding to remove excess dust or fines. In 1998, 33 percent of farms sieved feed compared with 25 percent in 2003 illustrating the increased use of extruded diets by industry.

An important element of managing nutrient discharge is using diets with appropriately low levels of phosphorus (P). Phosphorous is a mineral that is essential for normal growth and metabolism in salmonids. The main source of P is the diet. Although the P requirement for salmonids ranges from 0.5 to 0.8 percent (NRC, 1993), it has historically been incorporated to excess in diets. Compared with standard diets containing P levels of 1.7 percent, diets with P levels as low as one percent are commercially available.

Chemicals and therapeutants

Chemicals may be used in fish farming for a number of purposes (Table 1), including:

DisinfectantsDisinfectants may be used to clean and washdown equipment as well as sanitise footwear. The use of disinfectants is an important component of best practice management in aquaculture as they reduce the risk of disease or pathogen transfer. Disinfectants commonly used are chlorine-based (e.g. Chlorofoam) or sodium hydroxide.

TherapeutantsUnder the Chemical and Veterinary Chemicals Code Act, 1994 all agricultural and veterinary chemicals (as defined by the Act) must be registered by the Australian Pesticides and Veterinary Medicines Authority (APVMA) before they can be supplied, sold or used in Australia.

Chemicals used for therapeutic purposes in aquaculture include topical treatments applied externally and enteral treatments incorporated into diets. Topical treatments are infrequently used in salmonid aquaculture and their use is confined to hatchery production. It is usually prohibitively expensive to use this type of treatment in open ponds.

The most commonly used topical treatments are formalin and salt. When these chemicals are used in hatchery troughs, water flow is halted (and supplementary aeration applied) and sufficient stock chemical to attain concentrations of 30-100 ml/100 litre of formalin and up to 5 g/l of salt are applied. When the treatment is complete, freshwater flow is re-established and the treatment flushed from the treated tank.

Malachite green is a topical treatment that was commonly applied in aquaculture but is now prohibited.

Although common overseas, the use of antibiotics in salmonid aquaculture in Victoria is extremely rare. There are two recorded cases of antibiotic use in salmonid aquaculture in Victoria in the past 15 years. If they were used, it would be only in response to a catastrophic disease outbreak and must be administered under the supervision of a veterinary surgeon.

Feed additives Chemicals added to feeds include vitamins, minerals and pigments to ensure optimal growth, resistance to disease and product acceptance. Bioactive compounds such as antibiotics, hormones and certain minerals are not added to salmonid aquaculture diets except for specific applications (see Hormones below). Astaxanthin, a synthetic version of a naturally occurring carotenoid, is included in diets during the 12 weeks leading harvest to impart a pink colour to the animal.s flesh. Levels of pigment incorporated into diets ranges from 50 to 100 mg/kg.

Anaesthetics Anaesthetics are used to sedate fish prior to handling or harvest. Several fish anaesthetics are commonly available but only one is currently approved by the APVMA for use in aquaculture. MS 222, an aquaculture sedative commonly used in the North America, is not approved for use in aquaculture.

Hormones Hormones are used in hatcheries for manipulating the sex of stock or to induce spawning. Not all hatcheries use hormones.

Female salmonids have higher growth rates and are bigger than males (Piferrer, 2001) which tend to mature early and stop growing. The males continue to feed, increasing the farm.s FCR and lowering the quality of its product.

Methyl-testosterone has historically been used to masculinise swim-up fry so that, when they breed the next season, their progeny are all female. Only a small number of fry are treated in this manner (at a rate of 3 mg/kg in feed). The annual industry usage of this drug is unlikely to exceed 50 mg. The chemical is used under a permit from the APVMA and processes for re-registering the use in the salmonid industry are underway. Farmers need to have a permit under the Drugs, Poisons and Controlled Substances Act, 1981 to access the chemical and fish destined for human consumption are not treated with this hormone.

Ovaprim is a synthetic hormone that mimics the effects of the hormones that regulate the reproductive cycle in fish. It is used to induce spawning in broodstock.

Fuels Fuels such as diesel and petrol are used on salmonid farms for machinery and generators.

Table 1: Chemicals used in the Victorian salmonid industry

| Use | Chemical | Comments |

|---|---|---|

Disinfectants Sodium hydroxide | Chlorine-based Hydrogen peroxide |

|

|

Therapeutic Chemicals | Salt (sodium chloride) Formalin Antibiotics |

|

| Feed Additives | Pigments Vitamins and minerals Bioactive compounds |

|

| Anaesthetics | Isoeugenol |

|

| Hormones | Methyl-testosterone Ovaprim |

|

| Fuels | Diesel LPG |

|

Principal wastes from salmonid culture

Many environmental impacts of inland salmonid culture are associated with wastes generated during fish production. This section summarises the main wastes generated and the characteristics of these waste streams. Wastes can be defined as materials used during fish farming that are not removed during harvesting. In the case of salmonid aquaculture, wastes can be divided into the following categories:

- organic matter, mainly uneaten feed and fish excreta, in effluent;

- sludge from settlement ponds;

- chemicals and therapeutants;

- fish mortalities and processing wastes;

- fish escapes; and

- greenhouse gas emissions.

Effluent characteristics

Effluent from freshwater fish farms has solid and soluble fractions. Solid wastes are comprise mainly uneaten fish feed and faeces but can include solids suspended during cleaning of ponds or sediment basins. Soluble components are nitrogen (N) in the form of ammonia and urea produced by fish metabolism and excreted. Effluent quality and quantity is a product of several factors including:

- the quality and composition of feed administered and the efficiency with which it is fed (Food Conversion Ratio) and assimilated by the fish;

- water exchange rates in the system; and

- the degree of recycling and water treatment prior to discharge.

Due to different system efficiencies and feeding strategies, effluent can vary substantially in composition and magnitude between different sites. During 1988/1989, the EPA conducted a study to quantify effluent loads from three Victorian salmonid farms (Metzeling et al., 1993). The results are summarised in Table 2.

No recent studies on effluent quality can be used for direct comparison with the results of the 1988/1989 study. Industry monitoring has been conducted regularly since that study to comply with their EPA licence, but that data was not readily available for presentation in this report.

Substantial improvements in effluent quality are expected based on improved management practices. Numerous overseas studies have clearly demonstrated the link between improved management practices, particularly feed management, and improvements in effluent quality (Ackefors and Enell, 1994; Kelly et al., 1996; Axler et al., 1997). Improvements in effluent quality can also be quantified using the mass balance approach, which shows the impact on wastes discharged by reducing feed inputs and using better quality diets.

Following is a discussion of the principal components of aquaculture effluent.

Suspended solid loads Suspended solid loads from flow-through aquaculture systems are composed mainly of uneaten feed and fish faeces. A proportion of the feed remains uneaten in intensive systems and 25 to 30 percent of consumed food is egested as faeces (Beveridge et al., 1991). Solid loadings will also vary considerably depending upon the season, time of day, feeding rates, fish sizes and management practices such as pond or settlement pond cleaning.

Table 2: Loading rates (kg/day) of some water quality parameters from three Victorian fish farms during 1988/1989 (adapted from Metzeling et al. 1993)

| Source | Suspended Solids | Total Nitrogen | Total Phosphorous | Biochemical Oxygen Demand (5 day) |

|---|---|---|---|---|

| Farm 1 | 48-102 | 13-17 | 2.5-2.7 | 48-5A |

| Farm 2 | 4-28 | 4-8 | 0.9-1.8 | 34-36 |

| Farm 3 | 1100-1000 | 67-80 | 16.3--32.0 | 267-333 |

Nutrients Fish utilise N (as protein) and P for growth, as an energy source and for metabolic functions. Nitrogen and P are introduced to the system primarily as fish feeds that will either be eaten or wasted, depending on the efficiency with which the feed is delivered. Nutrients are also lost to the environment as faeces and other excreta. If feed management is poor, feed will be wasted, FCR will be high and higher nutrient loads will result. As with suspended solids, the type and amount of N and P released will vary daily and seasonally.

Organic matterEffluent contains biodegradable organic matter that can exert a biochemical or chemical oxygen demand (BOD or COD) on the receiving environment. Much of the biodegradable organic matter that produces the BOD and reduces dissolved oxygen (DO) concentration is present in the particulate fraction. Dissolved oxygen concentrations are also reduced through fish respiration and the combined effect results in a reduction in DO level as water passes through the fish farm.

Toxic metabolites

Some constituents of fish farm effluent can, under some circumstances, be directly toxic to fish and other biota. These include ammonia, nitrite and carbon dioxide.

Sludge from settlement ponds

Settlement and production ponds require regular cleaning to remove built-up sludge and to avoid the leaching of nutrients to the overlying water. This is achieved by draining the pond and physically removing sludge by shovel, backhoe or excavator. A continuous self-cleaning system such as a submersible sludge pump that moves across the base of the pond can also be used. In 2003, the majority of farmers indicated that settlement ponds were cleaned yearly. Current sludge disposal options include land application as a fertiliser, composting, on-site disposal in a pit, and landfill disposal.

The removal and concentration of suspended solids from production and settlement ponds results in a sludge that should be managed carefully and according to the waste management hierarchy (Environment Protection Act, 1970, section 1 (1I and 1J) reprint 14, July 2002 or later; EPA, 1990). Disturbing these settled solids can increase the solid loads discharged from the farm. Studies have reported that at an FCR of 1.2:1, one litre of sludge is produced for each kilogram of feed supplied (Bergheim et al., 1993).

Chemicals and therapeutants

Categories of chemicals that may be used on salmonid farms were outlined in Table 1. The quantity and type of chemicals that will enter the waste streams of a salmonid farm will depend on the mode of application. Chemicals most likely discharged as wastes are those administered directly to water (e.g. salt and formalin) and those contained in feeds (e.g pigments, vitamins and mineral and hormones).

The quantities of chemicals used are very low and will be diluted by water from the rest of the farm prior to discharge to the environment. Chemicals may also enter the waste stream through accidents or spills.

Fish mortalities and processing wastes

Fish mortalities occur during production, and regardless of the reasons for the mortality, require prompt removal from culture units and careful, effective management. Although routine fish mortalities are buried on-site at most large farms some facilities compost these wastes for use as pasture fertiliser.

Processing wastes are generated when fish are gilled and gutted on-site prior to transfer to market. The main wastes produced by fish processing operations are blood, viscera, heads and frames (i.e. offal). The survey indicated that around 235 tonnes of processing wastes are generated by the industry every year. The majority of farms bury this offal in pits on-site but an increasing number are composting with other primary products. Liquid wastes from fish processing are generally discharged to septic or sewer systems.

It should be noted that fish mortalities and processing wastes are prescribed wastes and can be disposed only to landfills licensed to accept this waste. The movement of these wastes is a scheduled activity and can be undertaken only with appropriate transport permits.

Fish escapes

Ponds are a relatively secure aquaculture production system; however, fish can escape through ill-fitting or poorly maintained screens or during handling or transport. Fish escapes can have a severe economic impact on salmonid farmers and it is in the farm.s interests to limit this loss. For this reason, large-scale escapes of fish from salmonid farms are uncommon. There are no data available on the number of fish that escape from Victorian salmonid farms each year.

Greenhouse gas emissions

The primary source of greenhouse gas emissions from salmonid farms is respiration of stocked fish. Fish excrete 1.4 grams of carbon dioxide (CO2) for every 1 gram of oxygen they consume (Summerfelt, 2002). Salmonids produce 0.3 to 0.4 grams of carbon dioxide for every 1 gram of feed consumed. Other sources of greenhouse gases include the fossil fuels burned to produce electricity for lighting, refrigeration, heating and cooling, petrol, diesel and LPG for transport and running generators and wood for smoking.

Regulation and legislation

This section summarises the statutory requirements of salmonid farming in Victoria as well as other non-legislative policies and strategies. Legislation of salmonid aquaculture falls into four general categories:

- planning legislation;

- water diversion legislation;

- fisheries legislation; and

- environmental legislation.

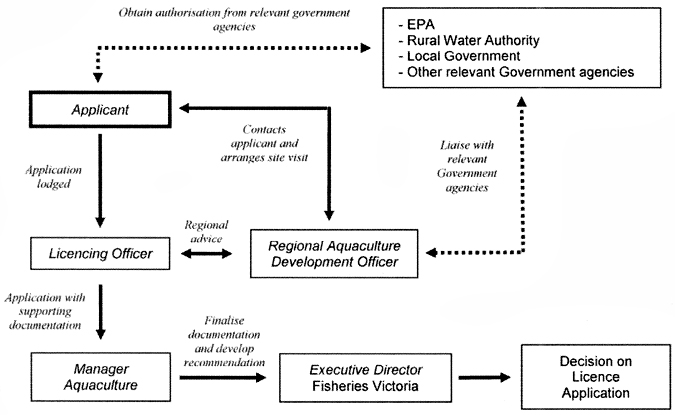

The process by which proponents apply for authorisation to conduct salmonid and other forms aquaculture on private land is summarised in Figure 4.

Planning guidelines have been issued to assist investors through the approval process (DPI, 2005).

Figure 4: The Victorian Fisheries Authority aquaculture licence application process

Planning legislation

For new farms, planning permission is required from the relevant local authority for the use and development of freehold land. The local authority also functions as the coordinating agency for referral agencies.

The Planning and Environment Act 1987 empowers planning authorities to make planning schemes over any land in Victoria including land that is covered by water (ORR, 1999). The Victorian Planning Provisions (VPP) is the reference document from which planning schemes are sourced and constructed.

Aquaculture is a discretionary use in all VPP zones (DPI, 2005). The only exception may be Public Conservation and Resource Zones where a permit is not required subject to specified conditions; otherwise the use of these zones for aquaculture is prohibited. It is likely that only VPP Rural Zones may be appropriate for salmonid aquaculture although consideration would need to be given primarily to the visual appearance of any buildings.

Often the main purpose of the zone is to provide for the sustainable use of the land for extensive animal husbandry and crop raising. Although no specific mention is made of aquaculture, the use is nested within agriculture, and one could reasonably assume that these are the most appropriate zones for agricultural activities.

Water diversion legislation

Salmonid farming is classed as a non-consumptive user of water (i.e. the amount of water diverted is equal to the amount discharged back to the waterway) and a water diversion licence from a Rural Water Authority (RWA) is required under the Water Act 1989. A water diversion licence provides conditions for the extraction and utilisation of water from a waterway or bore and provides specifications for alterations to a riverine environment required for the purpose of extracting that water. It authorises licence holders to divert and use a specified amount of water in megalitres (ML) from a specified waterway for aquaculture purposes. It stipulates the maximum rate of diversion (ML/day), maximum daily volume, total annual volume and land on which the water is to be used.

When processing licence applications, a RWA considers several factors including:

- existing and projected availability of water and water quality in the area;

- adverse effects on the riverine and riparian environment;

- the drainage regime and existing water use;

- the amount of water to which the applicant is already entitled;

- the volume of water allocated for sale;

- the need to protect the environment;

- government policies about the preferred allocation or use of water resources;

- the Heritage Rivers Act 1992;

- the proper management of the waterway and its surrounds; and

- how the water is to be used and needs of other potential applicants.

There is no guarantee of water quality and the licensee is required to comply with the conditions of the licence. The applicant may need to provide information on:

- daily flow rate requirements;

- low flow frequency in the waterway and flooding characteristics of the area;

- type of proposed diversion works and outfall works, including engineering drawings;

- flow monitoring proposals;

- operating arrangements;

- distances between diversion and discharge; and

- existing water quality and water quality impacts of the proposal.

Authorisation to undertake works on waterways

A waterways work permit is required from the relevant Catchment Management Authority (CMA) before any work is undertaken on waterway. This requirement applies to works within the bed and on the banks of waterways. The permit is issued under the CMA.s waterway protection by-law (made under the Water Act 1989).

Fisheries legislation

Under the Fisheries Act 1995 (the Act), an aquaculture licence is required from The Victorian Fisheries Authority to operate a fish farm in Victoria on both private and Crown land. An aquaculture licence is annually renewable and authorises the holder to use, form or create habitats on private land for commercial aquaculture purposes and to hatch, grow and hold permitted fish for commercial aquaculture purposes.

Entitlements and conditions of an Aquaculture (Private Land) Licence are provided in the Fisheries Regulations 1998. The Act also provides for the protection of both recreational and commercial fisheries, protected aquatic biota, including those listed under the Flora and Fauna Guarantee Act 1988, and protection against the introduction and spread of declared noxious or prohibited aquatic species and notifiable diseases.

A General Permit - Aquaculture Research can also be issued for a variety of purposes such as aquaculture project development and economic research. Permits are issued for up to three years. An aquaculture permit is an annual, renewable, fee-based authorisation which is described in more detail in the Fisheries Regulations 1998.

Environmental legislation

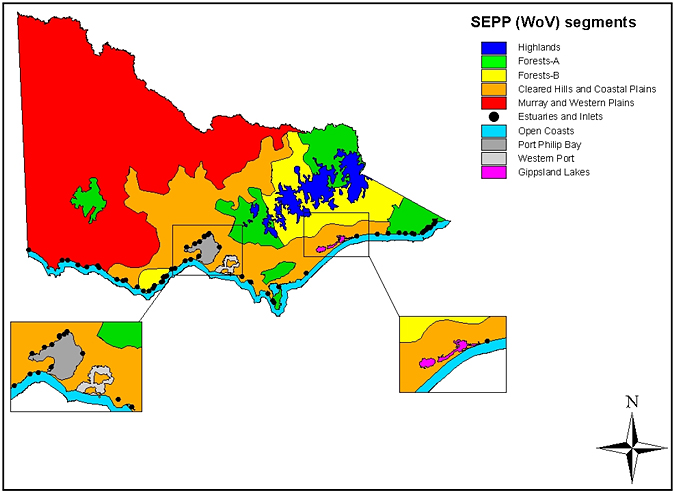

The Environment Protection Act 1970 and its subordinate legislation, State Environment Protection Policies (SEPP), are designed to protect beneficial uses downstream of any discharge or activity (licensed or otherwise). The EPA is responsible for preparing and recommending SEPP to government and it is the responsibility of all government agencies, industries and communities to implement SEPP requirements. The SEPP (Waters of Victoria) and its schedules identify beneficial uses (Table 3) for particular segments of the environment (Figure 5) and establish ambient water quality objectives (Appendix 2) (Victorian Government Gazette, 2003).

To protect beneficial uses, the discharge of wastewater to surface waters must be managed to minimise environmental risks. The EPA is responsible for implementing the SEPP (Waters of Victoria) and intends to do this with the salmonid aquaculture industry through:

- revising existing licences to ensure they are consistent with the policies;

- requiring licence holders to assess options for implementing the waste hierarchy and develop improvement plans to implement the preferred options and to reduce impacts of discharges on beneficial uses; and

- approving a mixing zone as part of a discharge licence where a discharge cannot practicably be avoided, re-used and recycled and where wastewater management practices are not effective.

Proponents of new and expanding salmonid farms must ensure their farming activities do not compromise beneficial uses reliant on the quality of water, particularly those posed by inputs of nutrients, pathogens and aquatic pests. Most salmonid farms are located in the highlands and forestry zones and rely on a high quality water resource. The beneficial uses of these zones must be preserved to ensure the sustainability of the industry. The impact of discharge from salmonid farms on nutrient concentrations in receiving waters should be determined at a range of environmental flows (especially base flows) specific to the site or catchment, to ensure the environmental quality objectives are not exceeded.

Fish farms with a design flow rate of 0.2 ML/day or more are designated as Scheduled Premises under the Environment Protection (Scheduled Premises and Exemptions) Regulations 1996 and are subject to the works approval and discharge licensing provisions of the Environment Protection Act 1970. Only fish farms discharging or depositing waste solely to land are exempt from licensing.

The licence review to be undertaken by the EPA will develop licence conditions for discharges using environmental quality objectives and a risk assessment based on an understanding of the health of receiving waters. Compliance with licence conditions will ensure the impacts of discharges are minimised to protect the beneficial uses of receiving waters. Appropriate monitoring is needed to demonstrate compliance and monitoring requirements will be outlined in the licence.

As part of an up-to-date EPA discharge licence, the licensee will be required to:

- monitor water flow and quality through the farm as well as other waste streams, their volume and management;

- provide a plan for environmental improvement;

- undertake annual reviews of the operation and submit an annual report, including progress towards environmental objectives; and

- notify the EPA of all major events that may impact on the quality of wastewater leaving the property or the overall operation of the farm.

If a mixing zone is required for an existing or new operation, it must be approved by the EPA and will constitute part of an overall discharge licence. The geographic extent of this zone and the water quality objectives to be achieved need to be determined by the licence holder.

Information required to determine acceptable minimum dilution factors within receiving waters includes:

- average monthly and daily flow distribution within the waterway;

- minimum mean daily flow distribution within the waterway;

- nutrient concentrations in discharge water; and

- minimum, monthly and average effluent dilution calculations.

Animal effluent and residues including fish processing wastes are classified as prescribed wastes (Schedule 1, Environment Protection (Prescribed Waste) Regulations 1998), and requires conditions detailed in regulations to be adhered to when transporting and depositing waste off-site.

Table 3: Beneficial uses to be protected (Victorian Government Gazette, 2003)View Table 3

F6: refer to beneficial uses set in SEPP (Waters of Victoria) - Schedule F6. Waters of Port Phillip Bay

F8: refer to beneficial uses set in SEPP (Waters of Victoria) - Schedule F8. Waters of Western Port and Catchment

F3: refer to beneficial uses set in SEPP (Waters of Victoria) - Schedule F3. Gippsland and Catchment

nb. Schedules F8 and F3 include marine and estuarine segments as well as rivers and streams within the catchments. Schedules F7 (Waters of the Yarra Catchment) and F5 (Waters of the Latrobe and Thomson Rivers and catchment) include beneficial uses for the relevant waterways.

Figure 5: SEPP (Waters of Victoria) and its schedules environment segments (Victorian Government Gazette, 2003)

Identifying and evaluating environmental issues

The aquaculture industry has a complex interaction with the environment on which it relies to provide a suitable culture medium for stocked fish and to dilute and disperse culture wastes. It is in the interests of aquaculture companies to ensure a clean, safe environment in and around their farms (Cripps, 1994).

This section identifies the environmental issues associated with salmonid aquaculture, and evaluates and prioritises these issues for industry. The issues identified as significant may be more or less important to an individual farm. Many of the impacts detailed here will be site specific, depending upon the location, size and management of the farm. The industry-level assessment was more complex than single site assessments as it encompassed a wider range of potential impacts. The ranking system prioritises environmental issues that the industry should address in order of importance and is not an assessment or ranking of actual impacts on the environment from salmonid aquaculture.

Environmental issues were evaluated and prioritised for the salmonid sector using a standard assessment process. The results were debated at a workshop with representatives of the salmonid aquaculture industry and relevant government agencies held at PIRVic, Snobs Creek on 28 May 2004.

Impacts of salmonid aquaculture on the environment

The environmental considerations which should be examined when developing and operating a fish farm include (after Gavine et al., 1996):

- impacts on the aquatic ecosystems including beneficial uses as specified in the SEPP (Waters of Victoria) and its schedules (Victorian Government Gazette, 2003);

- impacts on indigenous flora and fauna;

- impacts on humans in terms of nuisance or health risks; and

- impacts on the wider global environment.

Impacts on aquatic ecosystems

SEPP water quality objectives must be used as a benchmark for water quality, as they are the statutory requirement to ensure the protection of beneficial uses within that segment. As discussed in Section 3, the SEPP (Waters of Victoria) and its schedules require that aquaculture activities do not negatively impact on the stated beneficial uses of the fish farm segment. In practice this means downstream water quality should not deteriorate as a result of wastes to the extent that it has a detrimental impact on aquatic ecosystems or is rendered unsuitable for other users. Compliance with licence conditions will ensure that the impacts of discharges are minimised.

Potential impacts of aquaculture on aquatic ecosystems include:

- impacts of effluent discharge on the quality of surface waters;

- impacts of water abstraction on water sources; and

- impacts of other waste sources (e.g. mortalities and processing wastes) on surface waters.

Issues associated with each of the above were assessed individually. The results are summarised in Table 4 and explained in detail on the next page.

| Category | Specific Issue | Best Management Practices |

|---|---|---|

| Impacts of effluent discharge (catchment) |

|

|

| Impacts of effluent discharge (local) |

|

|

|

| |

|

| |

| Impacts of water abstraction |

|

|

| Impacts of mortalities and processing wastes |

|

|

Table 4: Issues related to impacts on the aquatic environment

Impacts of effluent discharge on the quality of surface waters

Aquaculture effluent can contain solid and soluble wastes with the potential to negatively impact on receiving water quality. The main issues include (Table 4):

- Nutrient enrichmentThe addition of nutrients to the receiving watercourse is one of the most ecologically significant impacts of fish farming (NCC, 1990). Nutrients (particularly P) in salmonid effluent are biologically available and may contribute to other sources of nutrients in the catchment (e.g. agriculture, sewage, and virgin bushland) and stimulate primary productivity (e.g. algal blooms) downstream in the catchment. Algal blooms can impact on downstream beneficial uses, particularly agriculture industries, recreation and tourism and domestic water supplies.

- Increased water turbidity and sedimentationSolid wastes discharged from fish farms are generally denser than water and, if current velocities are low, may settle out and accumulate downstream of the point of discharge. De-silting of ponds and settlement ponds can lead to additional solid loads in the effluent stream.

- Reduced dissolved oxygen levelsDissolved oxygen in effluent waters can be reduced through consumption of oxygen by the stocked fish and during bacterial breakdown of wastes. If the effluent is low in oxygen and or has a high oxygen demand, deoxygenation of the receiving waters can result in localised deterioration in water quality.

- Direct toxicitySome chemical constituents in the effluent (e.g. ammonia, nitrite, chemicals and therapeutants) can occur in forms or at levels that are toxic to resident biota. For example, ammonia toxicity increases with increasing pH and temperature, as the unionized fraction becomes dominant. Risks from direct toxicity can increase during periods of low flow periods and warmer weather.

- Catchment scale issuesFish farms that discharge to surface waters contribute to the total nutrient load of the catchment and as such increase the likelihood of algal blooms and other related downstream impacts. The importance of their contribution will be catchment-specific depending on the number and size of farms that discharge, nutrient loads from other sources and the sensitivity of the catchment to nutrient inputs.

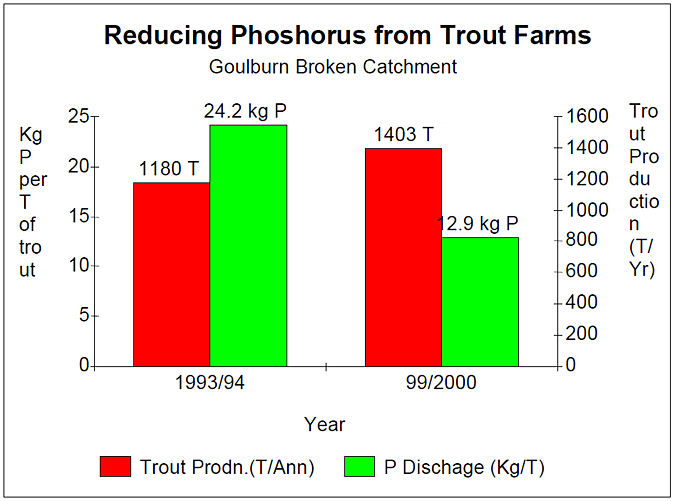

In areas where nutrients are of particular concern (e.g. Goulburn-Broken catchment where 16 of the 22 operating farms are located) the industry has made considerable efforts to reduce nutrient levels in effluent. Based on estimates for the 1993/1994 season, total P load from aquaculture facilities was, in 1998, limited to 28.6 tonnes (GBWQWG, 1995). Since 1993, the level of P discharged from trout farms has fallen from 28.3 tonnes to about 19 tonnes (equivalent to 12.9 kg/tonne of fish) in 1999/2000 (Figure 6). This is despite production increasing from 1,180 to1,403 tonnes during the same period (Ingram, 1999).

Figure 6: Phosphorous loads from fish farms in the Goulburn-Broken catchment in 1993/1994 and 1999/2000

- Local issuesLocalised impacts of fish farm effluent on water quality will be site specific and depend upon the quality and quantity of effluent and the capacity of the receiving watercourse to dilute and disperse the wastes.

Studies were conducted on the effects of fish farm effluent on water quality in upland Victorian watercourses in the late 1980.s and 1990.s (Metzeling et al., 1993; Metzeling et al., 1996; Metzeling, 1999). Although the studies showed that effluent quality is generally good compared with other industry discharges, nutrient levels in fish farm effluent are high compared with levels in receiving streams. The location of farms in high quality environments means adverse impacts occur especially during low flow conditions in the receiving watercourse. The large volumes discharged from salmonid farms are difficult to treat and nutrient enrichment impacts (e.g. algal and macrophyte blooms) can be significant on a local scale.

Increased water turbidity and sedimentation can result from pond de-silting. Once removed from the pond, sludges may be settled or dried to reduce volume and concentrated solids can be disposed of in pits or used as a fertiliser. Pond desilting is generally infrequent and the consequences are likely to be minor to moderate and dependent and site- specific. There is no record of long-term or significant impacts of solid waste discharges of this nature from Victorian farms.

As DO must be maintained at high levels for fish culture so reduced DO levels in receiving waters should not occur during routine operations. Low DO can occur as a result of pond de-silting or when flows in receiving water are exceptionally low but, as low DO will be replenished by water flow, the consequences are likely to be transient.

Similarly, levels of metabolites (e.g. ammonia and nitrite) discharged in effluent should not be toxic to aquatic life. Elevated concentrations of metabolites can occur under certain circumstances (see above) but the consequences are likely to be transient.

The impact of chemicals and therapeutants on water quality in the receiving watercourse will depend on quantities used, toxicity of the compound to aquatic biota, the rate of breakdown in the environment and the dilution afforded by the farm water flow and receiving water. Chemicals most likely discharged in the waste stream are salt and formalin, which are used as therapeutics, and feed additives (e.g. pigments, vitamins and minerals). As salt and formalin are used in small quantities in hatcheries or infrequently to treat diseases, concentrations will be greatly diluted within the flow of the farm prior to discharge.

Impacts of water abstraction on surface water resources

The abstraction of water from rivers for fish farming can result in physical, chemical and biological changes in running-water habitats (NCC, 1990). Depletion of flow between the intake and outflow of farms may result in the following impacts (Table 4):

- changes in channel shape and patterns of sedimentation with consequences for siltation and subsequent water movement;

- loss of spawning or nursery areas for aquatic species;

- alteration to the biological communities of rivers through loss of dilution capacity between inflow and outflow, reduced turbulence and oxygenation; and

- backside intrusion from the need to install structures and channels into a river.

Although it does not cause the same level of concern as farms located on regulated rivers, water abstraction can be a major issue for farms located on unregulated rivers. Impacts related to water abstraction will vary widely between farms, with some farms located on unregulated rivers experiencing annual problems and others experiencing problems in extreme drought or other extraordinary conditions. The severity of impacts will also be site specific and depend upon the location of the farm, its water source and the severity of external impacts.

Similarly, the consequences of water abstraction on spawning and nursery areas and biological communities will be related to the severity and frequency of impacts as well as the ecological sensitivity of the receiving watercourse.

Key factors determining the scale of impact include the:

- Proportion of total flow abstractedDemand for water for salmonid farms is highest during the summer months when water temperatures are higher. For farms on regulated rivers, this period should coincide with the irrigation season when river flows are also high. For farms on unregulated rivers, problems may occur as peak water demand periods will coincide with low river flows.

- Distance between outfall and intakeFarms with large distances between intake and outfall on unregulated rivers may have a greater impact than other farms

- Impact of the inflow weir as a barrier for the passage of fish and other aquatic organisms

Impacts of mortalities and processing wastes on water resources

Mortalities and processing wastes are commonly disposed of by burial in pits located on-site. If these pits are not properly designed and maintained, contamination of local groundwater or surface waters can occur. Leachate from these pits will have a very high oxygen demand and contain high levels of substances such as ammonia and nitrite. The consequence of leachate reaching surface or groundwater, even though it is unlikely to occur, will result in moderate environmental harm. (Table 4).

As pits require EPAapproval before construction, the likelihood of impacts occurring is low.

Impacts on flora and fauna

Impacts on indigenous flora and fauna can occur during construction and operation of the aquaculture facility. Three main areas of concern identified with respect to indigenous flora and fauna are (Table 5):

- destruction or alteration of habitats during construction and operation;

- interactions with mammals and birds; and

- interactions with native fish populations.

Destruction or alteration of habitats during farm construction and operation

Habitats of indigenous flora and fauna can be destroyed during clearing of land, draining of wetlands for construction and earth moving. Clearing of native flora can significantly impact the biodiversity of local flora and fauna, particularly where threatened or endangered species are involved. Other issues may arise from the disturbance of riparian vegetation that can increase erosion rates and affect the hydrology of local rivers reducing water quality and smothering aquatic habitats.

Table 5: Potential impacts of salmonid farms on flora and fauna

| Category | Specific Issue | Best Management Practices |

|---|---|---|

| Destruction or alteration of habitats |

|

|

|

| |

|

| |

| Interactions with birds and mammals. |

|

|

|

| |

| Interactions with native fish |

|

|

|

| |

|

|

Impacts will be minor to moderate, as all activities require planning permission and EPA approval. As new farms are approved infrequently, the likelihood of this issue occurring is considered to be low.

Similarly, construction on established industry sites must receive permits from the local authorities and the EPA, so consequences should be minor to moderate. These events might take place where farms are re-designed or retrofitted to improve their environmental performance.

Alteration of habitats during the operation of salmonid farms relates to the ecological consequences of modifications in water and sediment quality described earlier and as such will occur with the same frequency. Specific issues include the smothering of aquatic benthic habitats by accumulated solids, water quality unsuitable for aquatic life and loss of habitats or spawning areas between intake and outfalls.

The consequences of this will be site specific, depending on:

- the quality and quantity of effluent discharged, the capacity of the river to dilute and disperse wastes and the ecological sensitivity of the river; and

- the distance between intake and outfall and the proportion of the flow diverted.

Interactions with birds and mammals

Fish-eating birds and mammals are attracted to aquaculture sites due to the availability of fish and feeds. They can cause problems for fish farmers as they harass and prey on stock, which can cause significant economic damage. Aquatic and terrestrial mammals (e.g. kangaroos and wombats) can interact with fish farms and potentially damage infrastructure as well as raise occupational health and safety (OH&S) issues (e.g. wombat holes). Farmers usually employ predator control measures (such as fencing, netting, scarers and guards) to restrict the entry of or scare off fisheating predators.

Assessment of issues related to birds and mammals

Although interactions with predatory birds are highly likely to occur, simple countermeasures that have low impact on those bird populations can be implemented. Terrestrial and aquatic mammals may encroach onto farms but environmental consequences will depend on the type of mammal, the extent to which it causes a problem and exclusion measures used.

Installing anti-bird netting over production units, using scare guns and removing any potential food sources (e.g. mortalities and processing wastes) can reduce the attractiveness of a site to birds and mammals.

Interactions with native fish populations.

Fish farming can affect native fish in the following ways (NCC, 1990):

- modification of habitat;

- the escape of non-native species that may prey upon or compete with native stocks limited resources and, in large numbers, can reduce genetic diversity within the community;

- disease transmission to native stocks; and

- impact of hormones or bioactive compounds on native fish breeding cycles.

As escaped fish are a financial loss to the farmer and cause impacts on the environment, salmonid farms are designed to hold fish securely within the farm. Ponds are built to prevent overflow in extreme weather and are securely screened to prevent fish from moving between and out of them.

A large-scale escape of salmonids will have an impact on native species but the likelihood of this occurring is relatively low. Breeding populations of rainbow trout and brown trout are present in the rivers where Victoria salmonid farms are located and a large number of salmonids are released each year by the Victorian Government and angling clubs in re-stocking programs. The consequences of escapes of salmonids on native fish populations are likely to be relatively minor.

The likelihood of disease transmission to wild stocks from intensive aquaculture is unlikely as scientific evidence suggests disease organisms present in farmed stocks are also present in wild stocks. Farmed fish are more susceptible to disease outbreaks as they are held under more intensive conditions and it appears that, when endemic, most pathogens in farmed stocks are acquired from wild fish (NCC, 1990). The consequences of exposure of wild fish to pathogens from aquaculture should not lead to widespread harm.

Concerns have been raised about the potential impacts of hormones or bioactive compounds on the breeding cycles of native fish. Bioactive compounds are not used in Victorian salmonid aquaculture. Hormones are used in extremely small quantities in hatcheries on a small number of fish. Ovaprim, a synthetic hormone used to initiate spawning in broodstock, is injected directly in minute quantities and only reaches the environment through excretion. Methyl- testosterone is incorporated into feeds at a concentration of 3 mg/kg and administered to swim-up fry over a period of 70 days (Shepherd and Bromage, 1988). Only that contained in waste feed or excreta reaches the effluent stream; total industry usage is unlikely to exceed 50 mg per year.

Feed pellets break up as they pass through the farm and a proportion will be removed in sedimentation ponds prior to discharge. Native fish will be affected by methyl-testosterone in feed only if they consume waste feed over a prolonged period. Given the extent of dilution that the feed will receive from the larger farm and the receiving watercourse, this is highly unlikely.

Impacts on humans in terms of nuisance or risks to health

Table 6 lists the issues that may impact on humans living or working at or in the vicinity of fish farms.

Visual impacts

These impacts relate to the visual intrusion of buildings, culture facilities (e.g. ponds and raceways) and the appearance of the site may have in agricultural landscapes.

Fish farms use buildings and equipment installations similar to those used in other forms of terrestrial farming, so their visual impact is low. Ponds are either very low profile or level with ground elevation and provide little visual intrusion. Inflow and outflow points may have continuously operating equipment and security lighting. Visual issues could arise from poor farm management through scattered equipment and litter. In general, the visual impacts of fish farms are not significant and most blend in well with the agricultural landscape.

Table 6: Potential impacts of salmonid farms on humans

| Category | Specific Issue | Best Management Practices |

|---|---|---|

| Visual Impacts |

|

|

| Noise |

|

|

| Odour |

|

|

Noise

Most fish farms regularly use machinery or undertake activities that cause some form of noise. As farms are situated in rural areas, these noises are commonplace and do not generally cause a nuisance.

Fish farm noise usually comes from continuously running mechanical equipment such as pumps and aerators. Intermittent noise can result from construction activities, use of heavy vehicles for transporting stock and feed, and equipment used to scare predatory birds. Interim guidelines giving acceptable noise levels at different times of the day are in place for control of noise from industry in rural areas (EPA, 1989).

Odours

Although all farms generate wastes that may cause odour problems, the majority handle wastes appropriately so odour problems are infrequent and the consequences transient.

Unpleasant odours from fish farms come from solid organic wastes, mortalities and the byproducts of processing. Disposal of processing waste products and fish mortalities on-site can also generate odour problems and raise other operational considerations.

Impacts on the wider global environment

Impacts on the wider global environment influence how the industry is perceived by the wider community.

Selection of fish diets

Fish food is a major input to aquaculture systems and its quality and the efficiency with which it is fed are important to effluent quality and production of sludge wastes. Agrowing issue for the aquaculture industry internationally is its apparent dependence on fishmeal-based diets.

Fishmeal is the product of wild-caught fish stocks, a number of which are classified as fully exploited, over-exploited or depleted (Naylor, 2000; FAO, 2002). Concerns that aquaculture is depleting wild fish stocks has captured the imagination of environmental groups and the media and is regularly cited as a negative impact of the aquaculture industry.